Sion Power, Muhlbauer to create manufacturing line for lithium metal EV battery cells

Charged

MAY 1, 2024

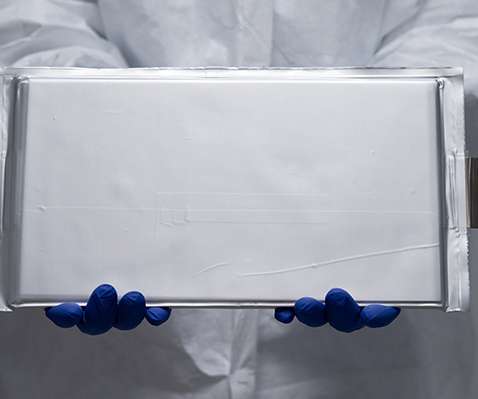

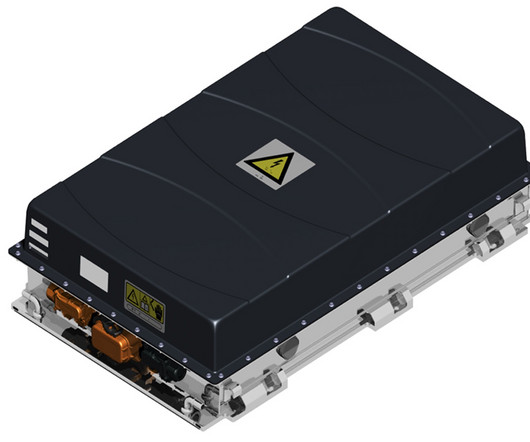

US-based EV battery developer Sion Power has formed a partnership with MB ATECH, the e-mobility division of Germany’s Muhlbauer Group, to create an automated manufacturing line for Sion Power’s large-format lithium metal cells for EV batteries. Licerion lithium metal batteries offer specific energy of to 500 Wh/kg.

Let's personalize your content