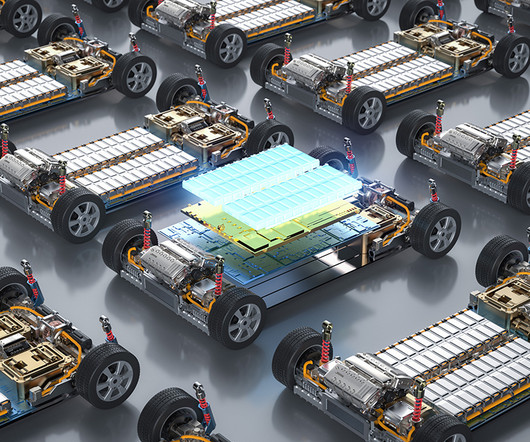

EV battery transport: How to overcome the challenges

Charged

APRIL 24, 2023

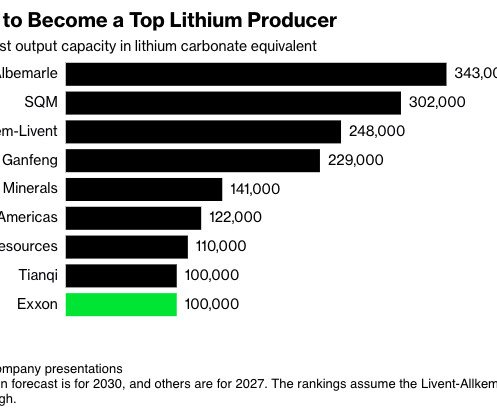

But the rapidly growing EV market has brought with it complex supply chain challenges associated with transporting the large format lithium-ion batteries that power them. And these challenges only increase depending on the size and condition of the battery. Why is transporting EV batteries difficult?

Let's personalize your content