Eavor publishes 4-year update on Eavor-Lite demonstration project in Canada

Eavor has published an update on the Eavor-Lite project in Alberta, Canada, demonstrating the performance of a multilateral closed-loop geothermal concept.

Eavor Technologies (Eavor) has published a paper on a comprehensive update on the Eavor-Lite demonstration project in Alberta, Canada. Operating since 2019, Eavor-Lite is a full-scale demonstration project of a multilateral closed-loop geothermal system that is currently being developed at a commercial scale in Geretsried in Bavaria, Germany. It has also served as a testbed for further research and development.

The full paper can be accessed via this link.

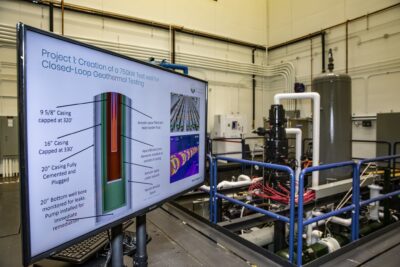

Eavor-lite is a prototype of the Eavor-Loop technology, consisting of a large U-tube shaped well with two multilaterals. The laterals are approximately 1700 meters long and have been drilled within the Rock Creek formation at 2400 meters depth.

Output and uptime

Eavor-Lite has produced 20 GWh of thermal energy since start-up. The original formation temperature at total vertical depth was 78 °C and a stable outlet temperature of about 50 °C was reached at a production rate of 20 cubic meters per hour after four years of operation.

Since startup, the system has had uptime of 96.2% including any downtime associated with system trials. Outside of those trials, the system reliability is at 99.6% with the only downtime attributed to a 3rd party power outage. Since Eavor-Lite does not produce electricity, a power loss triggers an emergency shutdown. For commercial-scale facilities that generate power, PLC logic will be programme to reduce the Eavor-Loop flowrate to the match the plant’s electrical load should a power loss occur.

Performance of open hole completion

The multilateral sections of an Eavor-Loop system are uncased. Instead, the Rock Pipe well completion technology reduces near wellbore permeability, thus reducing leak off into the formation.

The original in-situ permeability of the Rock Creek formation is estimated at 0.5 – 50 mD. After application of the Rock Pipe compound, the average permeability was reduced to 0.15 – 0.25 µD. This represents a reduction of 3 to 5 orders of magnitude.

Moreover, the current leak-off rate has been measured at about 0.4 cubic meters per day. Considering a production rate of 480 cubic meters per day, the system is considered to be 99.9% sealed.

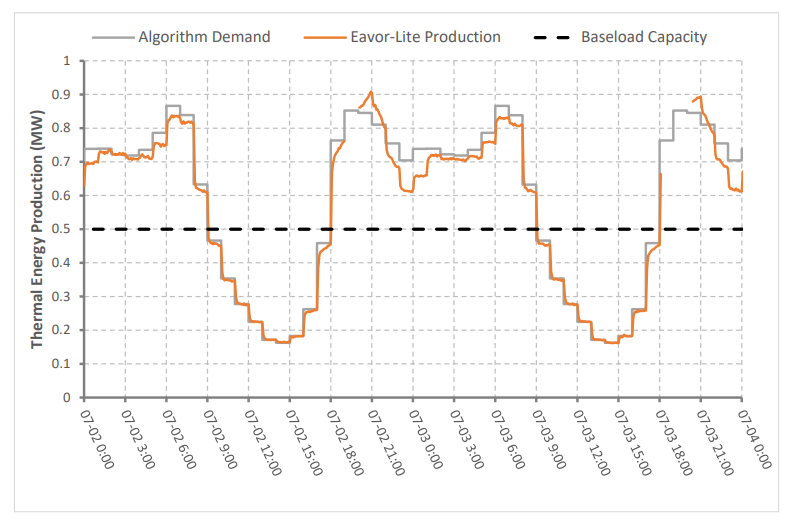

Load-following algorithm

The Eavor-Loop system is envisioned as a load-following resource, providing both baseload and dispatchable energy production to meet fluctuating demands over a 24-hour period. Anticipating fluctuations in energy demand and making the appropriate adjustments is difficult to perform manually. Hence, Eavor implemented a load-following algorithm to tuaomate the steps needed to produce a dispatchable energy curve.

Since Eavor-Lite is not connected to the power grid, the model used for the machine learning algorithm was an electricity generation “duck curve” typical of grids with high contribution from solar and wind power generation.

To meet the input demand curve, Eavor-Lite reduces production and stores the energy in the subsurface for production later in the day when it is needed.

The preliminary results show a satisfactory performance of the algorithm in converting an energy demand curve into actionable instructions that yield a production curve that matches the demand. The algorithm can also be customized to a variety of energy generation and demand contexts.

Learnings and future projects

In early 2023, Eavor completed the Eavor-Deep project in New Mexico, having drilled a two-leg multi-lateral well to a depth of 18,000 feet (~ 5480 meters) TVD with a temperature of approximately 250 °C. The project proved Eavor’s Insulated Drill Pipe (IDP) technology and the ability to drill in hot dry rock. Rock Pipe was also used to seal Eavor-Deep and reduce leak-off.

The Eavor-Lite pilot project served as a platform for development and validation of closed-loop thermodynamic models, as well as its long-term sustainability. It was also a vital testbed for research and development efforts, with the Eavor team running many trials at site to advance the understanding of the Eavor-Loop system. The lessons learned while operating Eavor-Lite are envisioned to help reduce operating costs for future projects.

Source: Eavor Technologies