Toshiba improving geothermal power plant performance with AI and IoT

Through the use of AI and IoT, Toshiba leverages hardware and software expertise to offer solutions for increasing the utilization of geothermal power plants.

A feature article published on Toshiba Clip, the official publication of Japanese multinational electronics company Toshiba, reports on how the company has utilized IoT and AI technologies to improve the utilization rate of geothermal power plants.

The feature article can be accessed in full via this link.

Predicting power plant issues

Toshiba has developed a “Trouble-Predictive Diagnosis Technology” for power plants that combines Internet of Things (IoT) and Artificial Intelligence (AI). The system employs EtaPRO, a plant monitoring software that collects various data from sensors installed in the facilities within the power plant. Using AI, the software compared current measured values with that of an expected operational state, thus detecting signs of anomalies or declining utilization rates.

Real-time monitoring allows for the early detection of potential issues and, ultimately, reduced plant downtime and improved efficiency. Hiroyuki Ichikawa of the Power Systems Division of Toshiba Energy Systems and Solutions Corporation describes the utilization of both hardware and software as one of the strengths of Toshiba.

“There are [also] challenges for existing geothermal power plants. It is difficult to secure and maintain the amount of geothermal steam generated from the ground, and it tends to decrease and deteriorate. In addition, the steam components contain sulfur and other substances that cause corrosion and deposition to equipment, resulting in deterioration of major equipment such as turbine generators,” added Chiaki Mogi, Deputy Manager for Global Marketing and Sales.

“As a result, the power generation has to be stopped every time the equipment is in maintenance, and the calendar day utilization rate is about 60%. How to improve the utilization rate of geothermal power plants is also an urgent issue.”

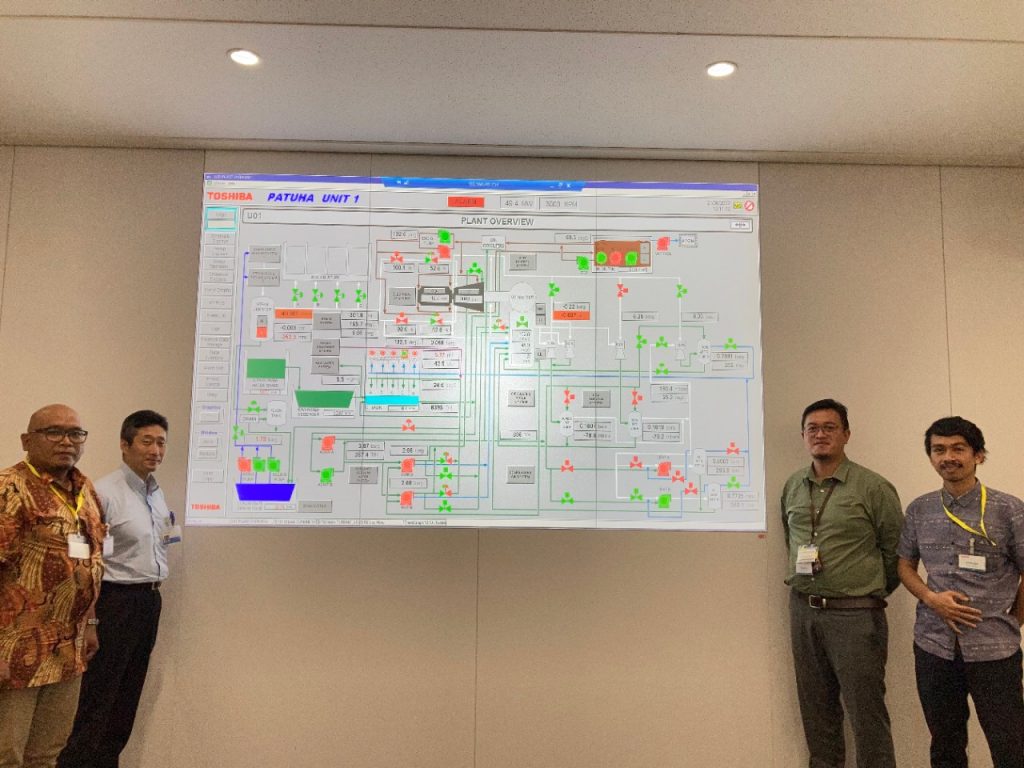

Deployment in Indonesia

A feasibility study for the deployment of the technology was done in Indonesia in 2019, specifically in the Patuha geothermal power plant of PT Geo Dipa Energi (GDE). This had resulted in a 20% reduction in the occurrence of power plant issues and a 2% increase in utilization rates. Even after the demonstration project, GDE continues to use EtaPRO and have been satisfied with the service.

“Utilizing EtaPRO, the real-time monitoring of equipment conditions directly from Toshiba’s headquarters has proven invaluable to us. This feature is particularly beneficial as we face limitations in the number of on-site engineers availability,” said Andisyah Purdanto, Maintenance Manager at GDE.

“Toshiba’s fast response and comprehensive performance reports have greatly facilitated our ability to address issues and enhance operational efficiency and reliability. Toshiba extends full support regarding equipment knowledge, root cause failure analysis, spare part availability, and technical advisory services.”

Towards digital transformation

The deployment of EtaPRO is a manifestation of Toshiba’s expertise in both software and hardware, which is a pillar of a digital transformation movement.

Ichikawa emphasizes the importance of real-time monitoring in geothermal power plants, where fluctuations in steam conditions are more likely compared to thermal power plants. “Geothermal power, influenced by the state of steam heated by magma, exhibits greater volatility in steam conditions compared to thermal power. As a result, determining abnormal values becomes more challenging.”

“However, our accumulated knowledge and data from supplying equipment to both thermal and geothermal power plants proved invaluable. We reconstructed databases and software, accounting for the ‘data noise’ inherent in geothermal power.”

Beyond trouble detection, the demonstration project has also been a test case for remote monitoring. The data collected from the Patuha geothermal power plant was monitored and analyzed by both GDE’s headquarters in Jakarta and Toshiba in Tokyo. If remote monitoring evolves into remote control of power plants, there can be further opportunities for improving plant efficiency. Reduced operational burden and advanced data analytics are two possible avenues.

Source: Toshiba Clip