Interview – The impact of GeothermEx on the geothermal industry in the last 50 years

In the first part of our interview with Ann Robertson-Tait of SLB’s GeothermEx™, we discuss the history of geothermal, emerging technologies, and O&G synergy.

Rarely do we see decades’ worth of experience combined with a mindset of innovation, but SLB’s GeothermEx™ is proof that the combination exists and that it is an essential component to remaining relevant in a constantly evolving geothermal industry. This year, the well-known geothermal consultancy celebrates its 50th anniversary—quite a feat in what is a relatively young sector.

To learn more about the history of GeothermEx and its continuing initiatives today as the geothermal consulting services arm of SLB’s geothermal business, we had an interview with Ann Robertson-Tait, president of GeothermEx. In this interview, Ann also discusses new technologies developed by SLB that can be valuable for geothermal, emerging technologies in the industry, and how oil and gas skills and technologies can enable geothermal advancement.

Read Part 2 of the interview here.

Congratulations again on the 50th anniversary of GeothermEx brand. Can you summarize the impact that GeothermEx has had on the geothermal sector in the last 50 years?

GeothermEx was founded in 1973, the year of the first major oil crisis. Geothermal had already started at The Geysers at that time, but the founders had the idea that there was still more space in an emerging geothermal industry. I didn’t join until 1985, but I’ve been with GeothermEx for almost 39 years, and am doing my best to carry on the GeothermEx legacy of today as part of SLB. The founders have retired, but they are thrilled to know that GeothermEx is still going strong.

The company was called “GeothermEx” because it was initially focused on exploration. Since then, GeothermEx has evolved, and we are a group that also includes drilling engineers and reservoir engineers, allowing us to cover all subsurface aspects of geothermal.

Our former VP of Reservoir Engineering did something truly innovative: In 1983, GeothermEx convinced a venerable New York bank (Morgan Guaranty Trust Company) to issue the first-ever non-recourse loan for a geothermal project. That geothermal project was the first unit at Salton Sea in Southern California, a field with extraordinarily high temperatures and a salinity of 260,000 parts per million. This “geothermal first” was the result of integrated geoscientific and reservoir engineering analyses in a very challenging resource, and it was a real breakthrough for geothermal in terms of getting projects financed. Many subsequent evaluations followed, and that continues to this day.

GeothermEx became known as the company that could be relied upon for independent analyses of resource capacity and sustainability. Our legacy of due diligence work—supporting more than 8.5 GW of geothermal power installed around the world—has helped the geothermal industry to grow. And we have been involved in an additional 2.5 GW—in total, about 70% of the world’s operating geothermal power projects. This experience gives us a broad perspective on how different types of resources can best be developed—and how they will evolve over time.

We have been influential in the geothermal power space not just because of our technical capabilities, but also because of the intensity and passion we bring to the job of financing geothermal projects. I think this was one of the most important elements in the history of GeothermEx. When we independently evaluate a project, we do so with objectivity and honesty. This means looking at the drilling and testing results, and occasionally disagreeing with the operator or developer when it comes to resource potential. We work through the issues to get consensus among the stakeholders, using prudent practices that minimize risk and maximize sustainability. These practices may include drilling more wells, optimizing injection well locations, or adding another flash cycle or heat exchanger.

We are creative people who really try to make geothermal happen. We believe in geothermal energy and want more of it to be developed. But we also want to do it the right way. We don’t want to get caught up in the hype rather than the reality. I would say that one of the most important things about our global geothermal work is the knowledge, integrity, and honesty that we put into every project.

The fact that we have seen so many resources around world in different geologic domains means that we have a breadth of knowledge that is probably unsurpassed by any geothermal company. When we see a project, we have the depth of knowledge across many types of geothermal resources to understand fairly quickly what the risks are likely to be, what problems will need to be to solved, what we can expect from the wells, and how much capacity each one can deliver.

How would you say has the geothermal development process changed in the past decades – technically, financially, or from a project management perspective?

We are seeing a digital transformation, which is something that we are also deep into as part of SLB. When we were acquired by SLB in 2010, GeothermEx became part of a company that is actively innovating in the field of geothermal. Let me cite a few examples.

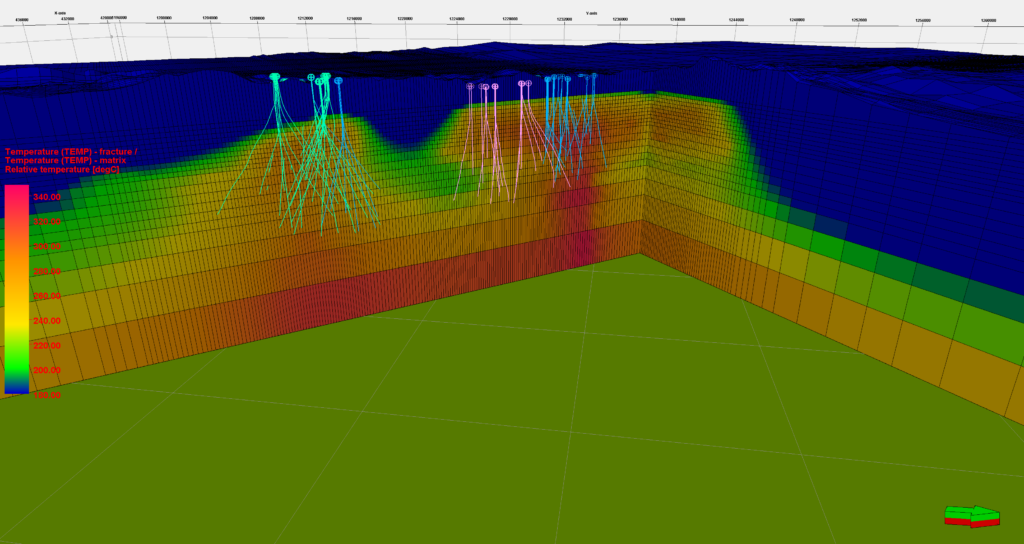

We are now using the multi-process simulator Eclipse™ which has long been used by the oil and gas industry. As resource complexity increases, we need to handle millions of grid blocks to properly model these resources, and computing time really starts to pile up. Using a multiprocessor simulator like Eclipse has made a huge difference in our reservoir engineering workflows. We now use Eclipse routinely and have perfected all the workflows to repurpose it for geothermal.

We also use the amazing engine of Petrel™, another SLB product, which is a tool not just for resource visualization, but also for the integration of incredible amounts of data such as subsurface temperature distributions, geology, geophysical data, and well trajectories. This kind of data integration through Petrel has been a key element to our success as we move with the times into more robust digital solutions.

As part of SLB, we are pushing for new technologies. One that I consider a game-changer in geothermal is high-temperature, high flow rate electrical submersible pumps (ESPs). Geothermal wells have massive flow rates—100 to 200 liters per second is what is needed. The previous temperature limit for geothermal pumps was 175°C. Without the ability to pump higher temperature wells, there was a gap in the productivity of geothermal wells.

We asked SLB for and received ESPs that operate at up to 225°C. This fills a technology gap that has existed for as long as I have been in the geothermal business. It’s an amazing product because it allows high temperature wells to be pumped for the first time at the high flow rates that we need. We find that customers really want this product. Sales are increasing and our customers are taking advantage of this innovation in about five or six countries at present.

Another technology that I would like to highlight are polycrystalline diamond compact (PDC) bits. Drilling and overall wellfield development accounts for about half of the cost of a geothermal project. Drilling faster, better, and cheaper can make a significant difference in the levelized cost of electricity (LCOE) of geothermal. PDC bits have been around for a while, and we have known that PDC bits are good for the hard rock environment that we have in geothermal.

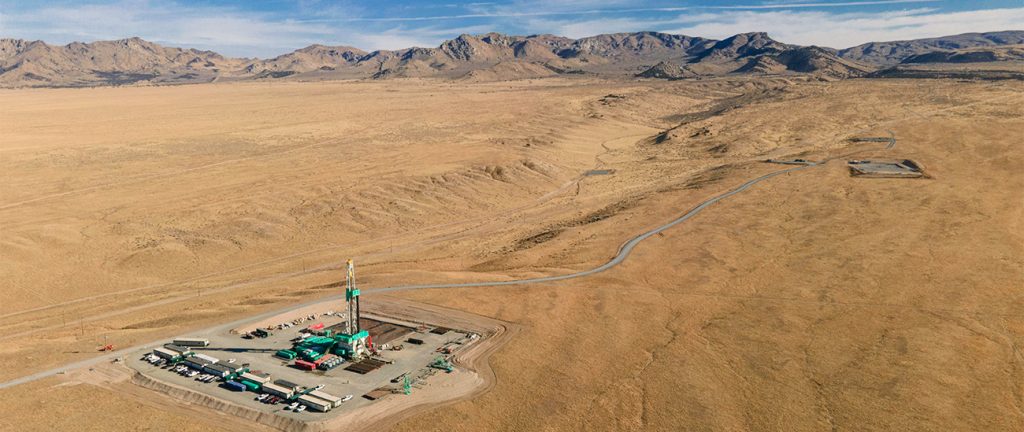

Just this year, SLB released a brand-new bit called ThermoBlade™, which is a thermal-resistant diamond element bit with a long bit life. This bit was tested in the Utah FORGE project where ThermoBlade won the contest of all bit technologies for drilling in granite. By a significant margin, it had the longest bit life of any of the wells tested in the trials run by the FORGE project.

So, when you’re talking about hard rock drilling, or high-temperature production of fluids, I can say that SLB has your back.

Despite geothermal going through a growth period nowadays, the industry is still waiting for a big breakthrough. Is there any specific emerging technology or new territory that you are very optimistic about?

There are a couple of them, but first I want to say that I don’t want to drop conventional geothermal. When we say conventional geothermal, we are referring to the resources that naturally have good temperature and good permeability. The 16 GW that has been developed so far are all supplied by conventional geothermal resources. The question has always been “How can it scale up?”

There are several things that we should talk about there. One is that there are still many untapped geothermal resources around the world. In the Philippines and Indonesia, you have two volcanic countries that have immense capacity that have not been developed to their full potential. Even in the United States, there is another 5–6 GW of natural, conventional geothermal systems that are untapped, and the same can be said for many other countries with conventional geothermal resources. This untapped potential of conventional geothermal should not be ignored.

As far as new technologies go, I will point to two unconventional geothermal resources: (1) Enhanced Geothermal Systems (EGS) like what Utah FORGE is working on, and (2) closed-loop technologies, also called the Advanced Geothermal Systems (AGS).

I became involved in EGS in 1999 when the US Department of Energy (DoE) was still calling this type of energy “hot dry rock.” They began to think about it in a different way at that time, realizing that geothermal is a spectrum—with hot dry rock at one end and conventional geothermal resources at the other. I was working with a consulting group in the Washington, DC area and there was a request from the DoE to change the name of this type of resource and to encourage developers of conventional geothermal resources to use certain elements that are common in EGS projects, including geomechanics, stress state and fracture analyses, which are directly applicable to conventional geothermal systems too.

Let’s fast-forward to today. EGS continues to be worked on. In addition to the excellent work being done at Utah FORGE, we are seeing commercial developers get into the EGS space, with Fervo Energy leading the way. Fervo has taken a page right out of the shale playbook, using shale technologies to fracture the rock quickly and effectively and enabling geothermal doublets to be drilled in record time.

If you think about the Earth, most of it is not made of naturally permeable rock. It can be hot, but much of it does not have high natural permeability. Conventional geothermal resources develop over thousands to millions of years to create their own permeability and cap rock. Now, we have a way to get past that and stimulate tight rock to become more permeable, creating the heat exchangers that nature did not. It’s great to see the advancements in EGS and I’m super excited to see at least one commercial developer of EGS.

We’re also participating in closed-loop geothermal through Celsius Energy, which is an SLB startup. This is a heating and cooling play using ground source heat pump technology but in a different way. The innovation here is a radial drilling pattern and heat recovery loops that go to depths of about 200 to 250 meters. This approach enables campus-scale heating and cooling solutions in office buildings, apartment buildings, medical centers, and industrial parks and universities, among others.

What can you say about the relationship of geothermal with oil and gas? Is the O&G industry an enabler of geothermal or is it a competitor?

The world of geothermal is expanding and we are seeing a lot of interest in heating and cooling and geothermal power in deep basins, the traditional domain of oil and gas. This is happening in many places, including the Middle East. A beneficial synergy is developing in this region, particularly because of the deep penetration of solar power and its effect on the stability of transmission grids. I think it’s so important that the Middle East embraces not only solar, but also geothermal energy.

We don’t consider oil and gas to be a competitor. We each learn from the other. I think that synergy is so important to get us through the energy transition, and that we cannot have geothermal at scale without the participation of oil and gas. It’s exciting to see interest in geothermal coming from countries like Saudi Arabia and Colombia, and the desire for it coming from both the oil and gas sector and the geothermal sector.

Let’s be honest—we use a lot of oil and gas technology for drilling and many other things. The technologies that I have mentioned that are part of SLB are great examples of how oil and gas technology and geothermal overlap with one another. Is every oil and gas company eager to get into geothermal? Maybe not, but many are.

A good example is Repsol in Spain. They have a strong desire for geothermal and, fortunately for them, they have the Canary Islands, which are likely to host good geothermal resources. There are other such companies, like ADNOC in the Middle East and Ecopetrol in Colombia.

These companies are thinking seriously about geothermal and we’re helping them to understand how they can extract geothermal fluids from their deep sedimentary basins. We’re working on quite a number of projects like this. I suppose the one that might be the most visible is the evaluation of geothermal potential of Oman. We’re just about to start the third and last phase of this evaluation.

The main point I would like to make is that oil and gas and geothermal need each other. Geothermal can benefit from the ability of oil and gas to scale up. We see this in the innovative companies starting up in Texas such as Sage Geosystems. They came right out of oil and gas and are developing an interesting downward reservoir stimulation technique, then pulling up heat up from depth in a hybrid open and closed-loop system. That is an example of innovation being done by people from the oil and gas space who really know the subsurface, especially the sedimentary basins.

I would say that it’s an exciting time, and two similar extractive industries—geothermal and oil and gas—are working more closely together than ever before.