Baker Hughes reports progress on Wells2Watts geothermal research consortium

Testing of closed-loop technologies is progressing at the Wells2Watts research consortium facility in Oklahoma, with field testing eyed later this year.

International energy service company Baker Hughes has published an excellent feature article on the progress of the research work being done as part of the Wells2Watts consortium. The full piece can be accessed via this link.

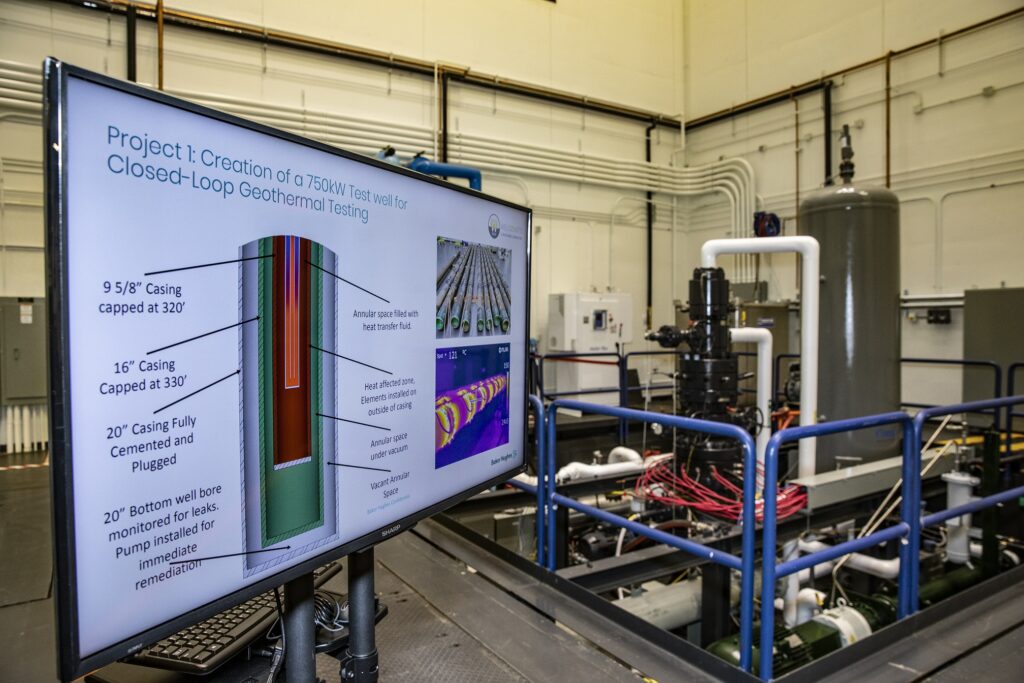

First announced in late 2022, the Wells2Watts consortium is led by Baker Hughes and aims to produce geothermal energy from abandoned oil and gas wells and non-productive geothermal wells. This is a private industrial partnership with Continental Resources, INPEX, Chesapeake Energy Corporation, and California Resources Corporation. The first consortium project will center around the test well that was commissioned in October 2023 at the Baker Hughes Energy Innovation Center located at the Hamm Institute for American Energy in Oklahoma City, Oklahoma.

“At the test well here in Oklahoma City we can test new geothermal technologies and also test how customers can use their existing infrastructure,” said Rob Klenner, Director of Geothermal Technology and Innovation with Baker Hughes and executive director of the Wells2Watts consortium.

“For example, where they’ve drilled oil and gas wells with high temperatures – that available heat could be used for geothermal. The idea is that they can transition an oil and gas well that’s no longer producing and become a renewable energy producer.”

The closed-loop test well is a 300-foot wellbore with 90 electric heaters coiled around the pipe, grouted at every 3 feet. This provides a controlled mechanism for heating the pipe from the outside to simulate geothermal reservoir conditions. The inner bore can be heated to a temperature of 450 °F (232 °C). Initial testing of closed-loop technologies have used GreenFire Energy’s GreenLoop technology and ICE Thermal Harvesting’s heat-to-power system.

Field testing planned later this year

The first field pilots of the Wells2Watts consortium is planned for later in 2024 with consortium partner California Resources Corporation (CRC) via the company’s carbon capture and sequestration business, Carbon TerraVault (CTV). CRC has a field outside of Bakersfield in California that is seen as ideal for the first pilot outside of the test well in Oklahoma City.

“We’re utilizing the skills and knowledge base of our employees who were previously extracting hydrocarbons to now injecting CO2 into depleted reservoirs to permanently store it away. Our interest in Wells2Watts is the possibility to repurpose our wellbores and depleted reservoirs to obtain geothermal energy,” said Chris Gould, Executive Vice President and Chief Sustainability Officer at CRC, and Managing Director of CTV Holdings.

A testing environment for new geothermal products

The closed-loop geothermal testing facility of the Wells2Watts consortium has also provided an excellent environment for product testing and development of allied services. One such example is the THERMOCASE® Vacuum Insulated Tubing (VIT) solution of French steel pipe and mechanical connections specialist Vallourec.

The vacuum-insulated tubing reduces heat loss from the bottom of the well as the fluid goes up the surface. “Imagine VIT as a ‘yeti’ cup – it’s keeping hot stuff hot and cold stuff cold. We pump cold water down one side of the tube and it heats up at the bottom of the well, producing hot water up the other side,” described Joe Hill, Vice President of New Energies North America at Vallourec.

Hill emphasizes how the Wells2Watts test facility provides a real-world counterpart to the proof-of-concept work that done one closed-loop geothermal, which has mostly been limited to computer modeling. “Wells2Watts gives us the opportunity to say, ‘We can model it and then we can test it and if those things line up then it’s easier for consortium members to put money for an in-field project.”

Source: Baker Hughes