Circu Li-ion co-founder and CEO Antoine Welter says his startup’s upcycling machine can diagnose batteries in seconds. “We know exactly which cell can be reused and which one can’t,” he told TechCrunch on Monday.

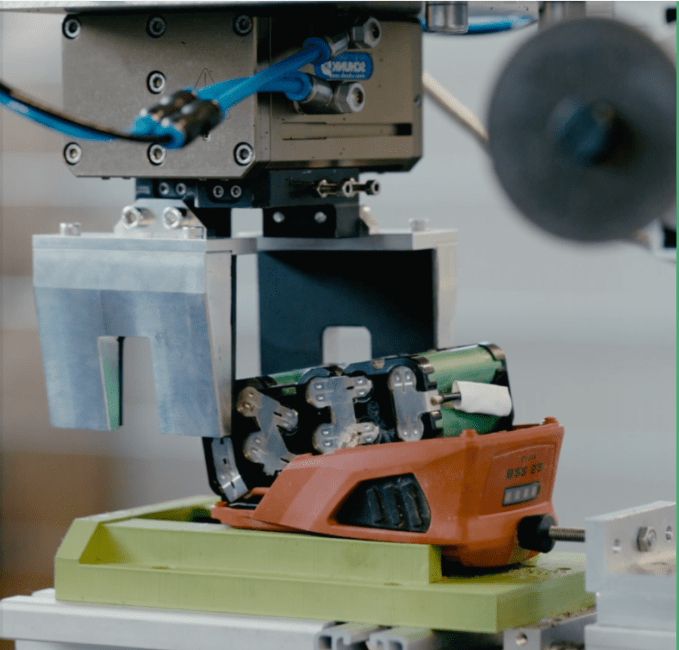

Circu Li-ion is in the business of saving usable battery cells from shredders. The Luxembourg startup’s machine identifies batteries by their appearance, via AI and a growing “battery library”; it separates cells from other materials, such as plastic housing and PCB boards; and it determines the cells’ states of heath.

Cells in great shape might go to use in mobility. When their condition is so-so, they might go on to store renewable energy. And cells that don’t make the cut go to a recycling facility.

Recyclers usually shred cells into black mass and recover valuable metals via smelting or leaching. Tons of components get mixed together and lost in the process.

Circu Li-ion’s machine separates battery cells from plastic housing and other materials, such as PVC boards. Image Credits: Circu Li-ion.

“There’s a lot of valuable materials that we can take away that don’t need to land in a shredder,” said Welter. Circu Li-ion claims that “more than eight out of ten cells in an end-of-life battery are actually not end of life.”

Welter was tight-lipped when asked exactly how the machine determines battery health.

“We collect more than 25 data points per cell” via EIS (Electrochemical Impedance Spectroscopy) testing, said Welter. “And based on those data points, we can — to a delta of 1.2% — determine how healthy the cell still is.” The CEO explained that testing an old cell is a little like interpreting the rings of a tree. “You can recognize different patterns and see how good the cell still is,” he added.

Image Credits: Circu Li-ion

Circu Li-ion charges manufactures and recyclers to use its machines and software. It also operates a facility in Karlsruhe, Germany, where it disassembles batteries.

In their past lives, so to speak, Welter worked as a B2B investor and consultant, while co-founder and CTO Xavier Kohll helped produce a “soft total artificial heart” at ETH Zurich, a Swiss research university.

Earlier this month, Circu Li-ion secured about $4.8 million (€4.5 million) in equity financing led by BonVenture, on top of around $4.2 million (€4 million) in earlier grants from the European Innovation Council Accelerator and other sources.

The startup said the combined $9 million or so in seed funding would help it scale its machine-as-a-service business model. Circu Li-ion said it also intends to build the “world’s largest” repository of battery recycling data.