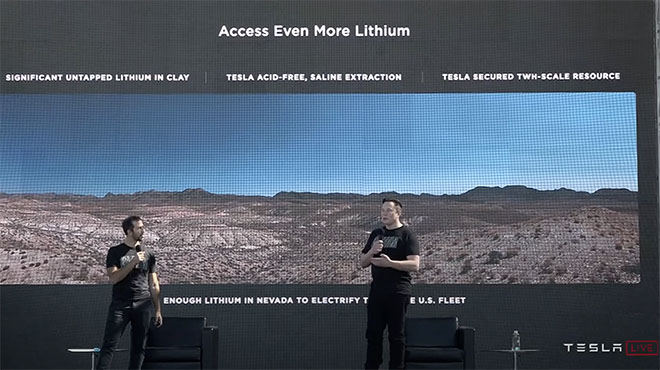

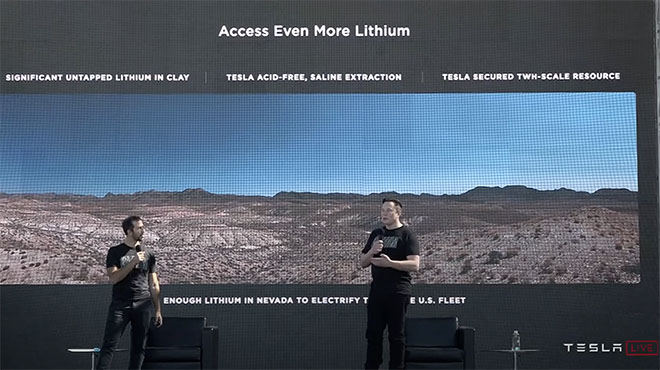

During last year’s Battery Day presentation, Tesla unveiled a number of new technologies, processes and plans, some of them only sketchily explained. One of these was a new lithium extraction process that Senior VP of Engineering Drew Baglino predicted could deliver as much as a 33% reduction in lithium costs.

“What is the best way to take the ore and extract the lithium and do so in an environmentally-friendly way?” asked Elon Musk. “We have been looking at [this] from a first-principle physics standpoint instead of just the way it has always been done. We found that we can actually use table salt, sodium chloride, to basically extract the lithium from the ore. Nobody has done this before to the best of my knowledge.”

Now Electrek has gotten access to a patent application for the new lithium extraction process, which reveals a lot more details.

In the application, entitled Selective Extraction of Lithium from Clay Minerals, Tesla describes some of the drawbacks of current extraction methods.

“The dominant lithium sources commonly used for mining are lithium brines due to the low cost associated with Li extraction from these brine sources. However, the ever-increasing demand for [lithium-ion batteries] makes it necessary to explore other lithium sources.

“Another method for Li extraction is to extract the Li from clay minerals. In this process, the lithium is obtained by acid leaching, where clay minerals are mixed with an aqueous solution of common mineral acids, such as H2SO4 or HCl, and then heated under atmospheric pressure to leach out the lithium contained in the clay minerals. This acid leach method not only leaches out lithium, but it also leaches out high concentrations of impurities including Na, K, Fe, Al, Ca, and Mg. High lithium loss from the subsequent removal of the impurity elements, especially Al removal, may significantly lower the overall lithium extraction efficiency. Furthermore, high acid consumption and complicated leach solution purification methods also make the overall extraction process less cost-effective and not environmentally friendly.”

Tesla summarizes its new proposed method:

“The extraction process includes providing a clay mineral comprising lithium, mixing a cation source [NaCl] with the clay mineral, performing a high-energy mill of the clay mineral, and performing a liquid leach to obtain a lithium-rich leach solution.”

The results of a chemical analysis indicate that the concentration of lithium in the resulting solution increases as milling time is increased, and that levels of impurities are comparatively low. Levels of aluminum and iron are negligible.

Electrek reports that Tesla plans to use the new process at its own lithium claim—a 10,000-acre tract in Nevada that the company acquired in 2020.

Source: Electrek