TE Connectivity‘s all-new TENDUR surface plating technology is designed to provide advanced abrasion resistance that allows for consistent high-performance charging over the course of a battery’s lifetime. The technology reduces wear and tear on electrical terminals, which can lead to longer charging times.

The newest high-powered charging stations can deliver DC power at currents of 500 amps or more. These high current levels often generate heat that can exceed safety thresholds, causing the charging apparatus to throttle back the current and slow charging speed. Public charging plugs can be damaged by abuse or exposure to abrasives such as dirt or salt, which can be transferred to the vehicle’s charging inlet as well as to other vehicles.

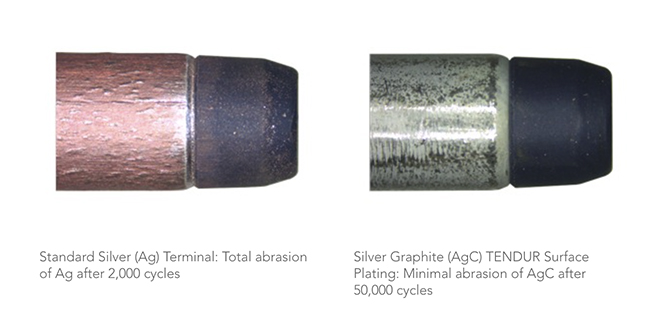

TENDUR contact plating comprises particles of graphite embedded in a silver coating. Together, they combine the electrical conductivity performance of silver with the self-lubricating advantages of graphite. The graphite serves as a lubricant which minimizes abrasion on any part of the contact zone during mating to negligible levels. Graphite is conductive, so TENDUR contact plating retains all the electrical performance properties of alternative hard-silver alloys (e.g. silver-copper, silver-palladium, silver-antimony).

Traditionally, plating technologies for charging inlets are rated to withstand up to 10,000 mating cycles. TENDUR has been tested to withstand 50,000 mating cycles with no contact zone abrasion.

“With our new TENDUR plating technology charging efficiency is maintained throughout the life of an EV, which in turn creates a better overall customer experience,” said Alberto Alamo Alonso, Product Manager at TE.

Source: TE Connectivity