This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Discovery enables cost-effective and eco-friendly green hydrogen production

A breakthrough technology has been developed that enables the production of green hydrogen in a more cost-effective and environmentally friendly manner, bringing us closer to a carbon-neutral society by replacing expensive precious metal catalysts.

Led by Professor Jungki Ryu in the School of Energy and Chemical Engineering at UNIST and Professor Dong-Hwa Seo from the Department of Materials Science and Engineering at KAIST, a joint research team has successfully developed a bifunctional water electrolysis catalyst for the high-efficiency and stable production of high-purity green hydrogen.

The newly developed catalyst exhibits exceptional durability even in highly corrosive acidic environments. By utilizing ruthenium, silicon, and tungsten (RuSiW), the catalyst is more cost-effective compared to conventional platinum (Pt) or iridium (Ir) catalysts. Furthermore, it emits significantly fewer greenhouse gases, making it an eco-friendly alternative.

The study is published in the journal Advanced Materials.

Water electrolysis is a cutting-edge technology that produces hydrogen through the process of electrolyzing water. It is considered a key technology for achieving a carbon-neutral society as it enables the production of environmentally friendly hydrogen without carbon emissions.

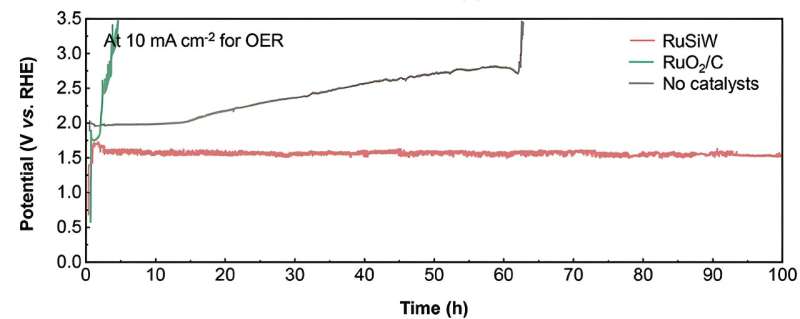

The research team focused on finding alternatives to precious metal catalysts like platinum and iridium, which exhibit stability in acidic conditions. Ruthenium has gained attention as an eco-friendly metal due to its relatively low production cost and significantly lower greenhouse gas emissions compared to platinum and iridium. However, it faced challenges in commercialization due to its lower catalytic activity compared to platinum and lower stability compared to iridium.

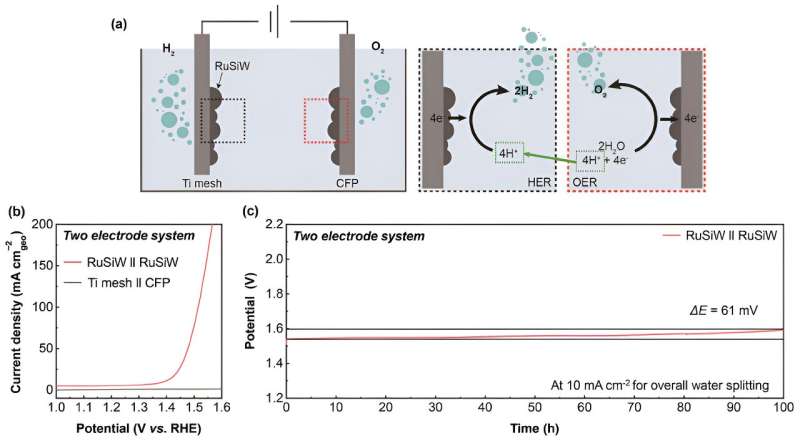

To overcome these limitations, the research team developed a catalyst based on ruthenium, silicon, and tungsten. By enhancing the function of the ruthenium catalyst, which has lower stability in both the hydrogen evolution reaction (HER) and the oxygen evolution reaction (OER), the team demonstrated the catalyst's potential as a bifunctional catalyst.

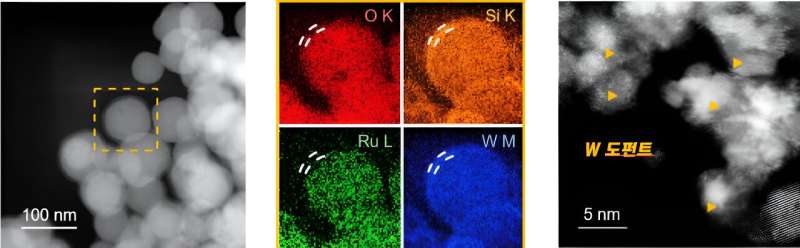

The developed catalyst features a structure doped with tungsten and silicon around a ruthenium atom. The catalyst's reaction acceleration ability was enhanced by increasing the adsorption intensity of protons on the catalyst surface. It exhibits higher activity in the hydrogen evolution reaction compared to commercially available platinum catalysts. Additionally, a thin tungsten film with a thickness of 5~10 nm protects the catalytic site of ruthenium, thereby improving its stability.

The research team conducted a stability experiment on the catalyst. Using an acidic electrolyte (with an acidity of 0.3), they injected 10 mA of current into a 1 cm2 electrode. The developed catalyst demonstrated stable performance even after running for more than 100 hours.

Professor Ryu stated, "The development of this three-element catalyst is significant as it has the potential to replace expensive platinum and iridium simultaneously. It is expected to be applied to high-purity green hydrogen production systems, such as PEM electrolyzers, as it can be easily and stably synthesized even in highly corrosive acidic conditions."

More information: Dasom Jeon et al, Electrochemical Evolution of Ru‐Based Polyoxometalates into Si,W‐Codoped RuOx for Acidic Overall Water Splitting, Advanced Materials (2023). DOI: 10.1002/adma.202304468