Aqua Metals has developed a novel battery recycling process. 6K Energy produces sustainable materials for lithium-ion batteries. That sounds like a natural match, and in fact the two firms recently signed a memorandum of understanding (MOU) to create a sustainable circular supply chain in the US for critical battery minerals.

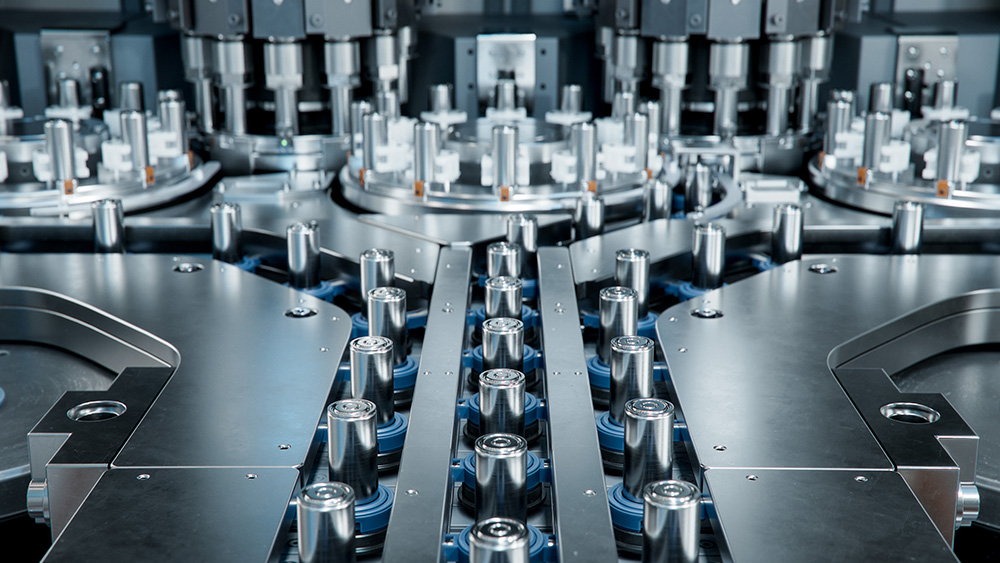

The partners’ plan outlines a joint venture to co-locate a full-scale battery recycling facility engineered and operated by Aqua Metals to supply 6K Energy’s PlusCAM cathode manufacturing plant in Tennessee. The co-located facility will use Aqua Metals’ Li AquaRefining recycling technology to convert spent batteries and manufacturing scraps into the raw materials for 6K Energy’s proprietary UniMelt CAM manufacturing process. The MOU includes a proposed supply agreement for recycled materials from Aqua Metals to meet the critical mineral needs of the 13,000-tonnes-per-year PlusCAM facility.

6K Energy has raised more than $350 million, including a $50-million grant from the DOE, to fund the buildout and expansion of PlusCAM facilities.

Aqua Metals currently operates a pilot battery recycling facility, and is developing a five-acre, 10,000-tonnes-per-year clean metals recycling campus in the Tahoe-Reno Industrial Center. Aqua has raised $275 million to support commercialization of its technology, and is applying for government-backed loans and grants to further accelerate commercial-scale deployments.

Aqua Metals’ patented AquaRefining technology recovers critical metals from spent lithium batteries using electricity in a closed loop, which the company says lower emissions, and reduces landfill waste by 95% compared to current battery recycling processes. 6K Energy’s UniMelt process is a microwave plasma production system, and the company says it delivers significantly lower emissions and reduced costs versus current cathode production methods.

“As the world grapples for control over the critical minerals essential for lithium batteries, together with 6K Energy we are building a resilient domestic supply chain,” said Steve Cotton, President and CEO of Aqua Metals. “Through our partnership we will be able to make the best use of these scarce resources, recycling them back into the value chain by creating cathode battery material from recycled content—strengthening US manufacturing capabilities and bolstering resilience to supply chain disruptions.”

“Our collaboration with Aqua Metals will create Li-ion battery cathode materials at production scales with recycled critical minerals,” said Sam Trinch, Group President of 6K Energy. “Together, we are building a robust supply chain for the technologies critical to combating climate change at a lower cost than China.”

Source: Aqua Metals