The head of the Australian company that has secured a landmark deal with Queensland government owned Stanwell for its iron flow battery products says Australia is the perfect place for the technology.

Energy Storage Industries is installing a first 1MW, 10 hour storage pilot of its iron flow batteries that are based around technology developed by Oregon-based ESS Inc, and this week revealed plans to build a 150MW facility, with up to 14 hours storage, which would make it the biggest of its type in the world.

The batteries used in Australia will be made in Queensland, at a facility in Maryborough.

ESi managing director Stuart Parry says Australia is a good place for this technology. Firstly, it is and will build lots of wind and solar, which needs storage, lots of it. It has plenty of iron – a cheap and abundant mineral in any case – and the “flow battery” technology uses methods very familiar with the minerals processing industry.

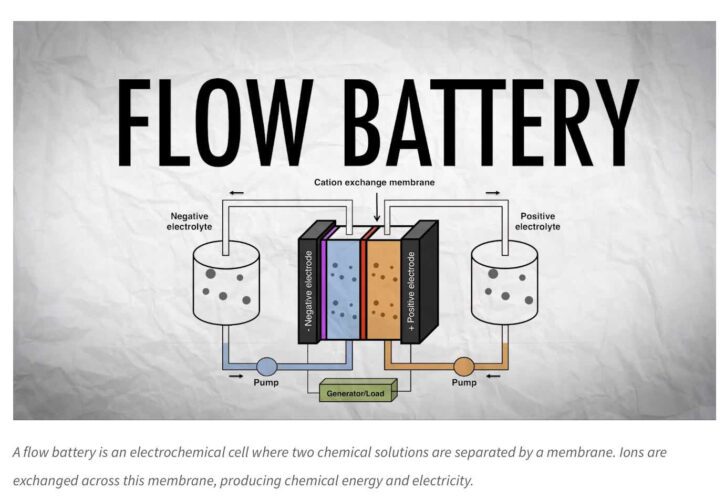

“It’s really quite basic,” Parry tells RenewEconomy. “We move an electrolyte past a membrane at a certain speed and pressure, and we have those skills from the mining industry. Australia has an engineering advantage here, and we can source the electrolyte … we don’t have supply chain risks.”

Flow batteries are different from lithium-based technologies in a bunch of different ways. They are not as quick or flexible, but they are expected to sit well in what Parry describes as the “baseload storage” market – between eight and fourteen hours that can transfer solar power, for instance, to last through the night.

They are also more easily recyclable – because they have no difficult or toxic components – and they are much less of a fire risk. And in the market where they will work best, they have a significant cost advantage over both lithium and pumped hydro, which is being weighed down by massive civil engineering costs.

Parry says the iron flow batteries “sacrifice a bit” on battery density, but can still deliver cheap power. “We see lithium batteries as a type of gas peaker, and pumped hydro is good “psychological support” for those fretting about wind and solar droughts, but is best suited for storage for days and weeks.

“We see the flow battery as baseload,” Parry says. “It can deliver over a 10 hour period, and you need to talk in terms that people understand. They don’t necessarily get firming and flexible capacity that fill in the gaps, but they do understand baseload.”

The ESI iron flow batteries will initially be installed in one megawatt blocks, but Parry sees the sweet spot as 5MW (50MWh). They won’t likely be in containers at that scale, but will need a larger floor space.

ESS says iron flow batteries circulate liquid electrolytes to charge and discharge electrons via a process called a redox reaction.

The word “redox” is a contraction of the words “reduction,” which represents a gain of electrons, and “oxidation,” or a loss of electrons.

ESS uses the same electrolyte on both the negative and positive sides of the equation, eliminating cross-contamination and degradation. This is why ESS chemistry remains stable for an unlimited number of deep-cycle charge and discharge cycles.

Other “flow batteries”, such as those made by another Australian company Redflow, uses different minerals as electrolytes. Flow batteries do not use lithium or cobalt.