UK-based laser manufacturer Luxinar is launching CO2 laser sources and femtosecond lasers that can shape battery cells and refine electronic components.

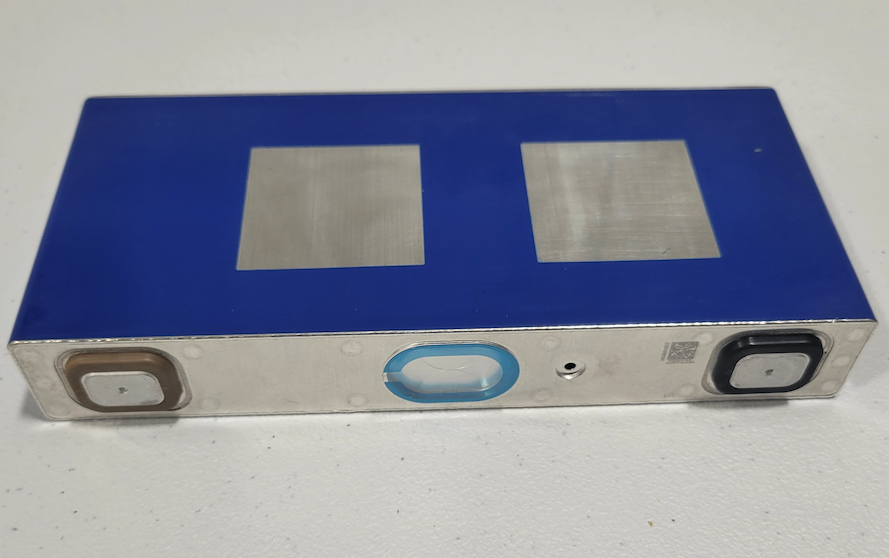

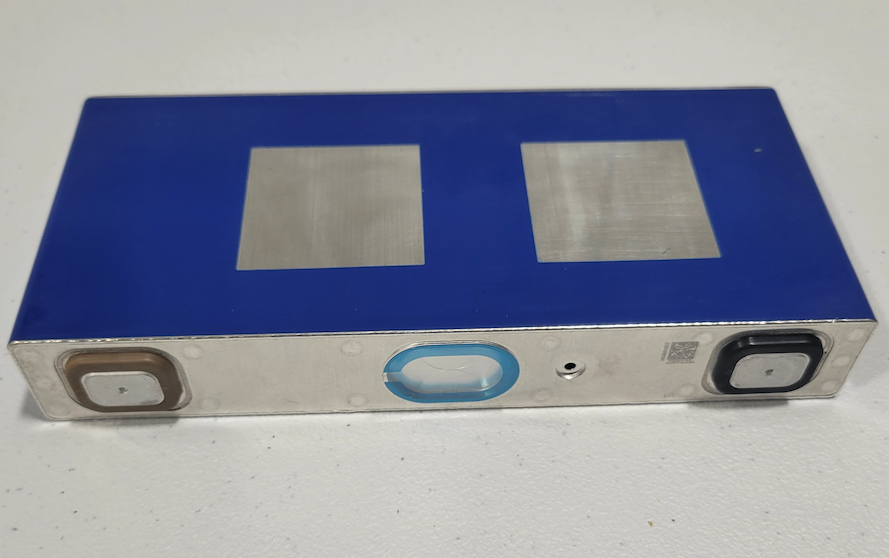

Luxinar’s battery cell applications include cutting separator foils and cutting and notching electrodes. Its battery module and power train applications comprise EV battery casing ablation and busbar isolation stripping and trimming, in addition to electric motor hairpin coating removal.

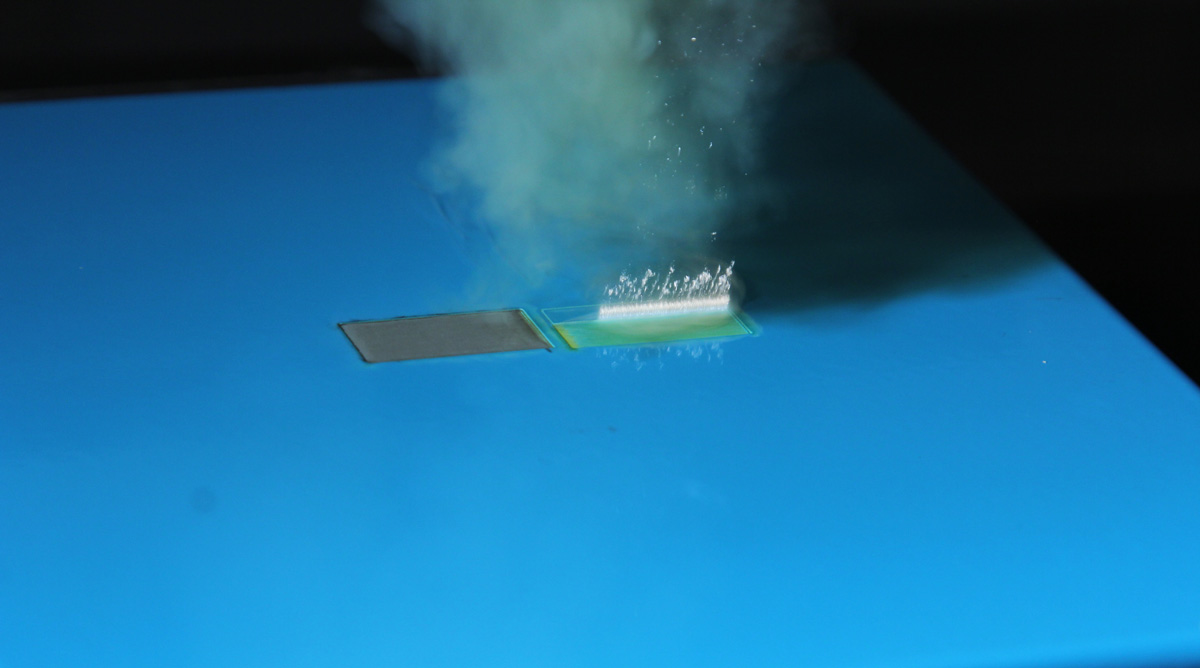

Automotive prismatic cells are frequently wrapped in a self-adhesive PET heat shrink film, which may need selective removal to add heat management components or complete removal to rework non-conforming cells in the production cycle. The film also needs to be removed when the battery is recycled. Using non-contact laser processing allows partial or full automation of the process and handling cells of different shapes and sizes in large volumes. Luxinar’s OEM 45iX CO2 laser process removes the need for harsh solvents and intensive mechanical effort to remove residue, according to the company.

“The versatility and precision of our laser technology makes various battery production tasks economically viable,” said Christian Dini, Luxinar’s Commercial Manager for Central and Northern Europe.

Source: Luxinar