Ferroglobe, a producer of silicon metal and ferroalloys, and Coreshell, a US-based battery technology company, have signed a memorandum of understanding under which they plan to produce battery-ready metallurgical silicon for the development of low-cost, high-range EV batteries.

Automakers are keen to use more silicon in anodes, because it can potentially store up to 10 times more energy than graphite. However, cycle life is a problem.

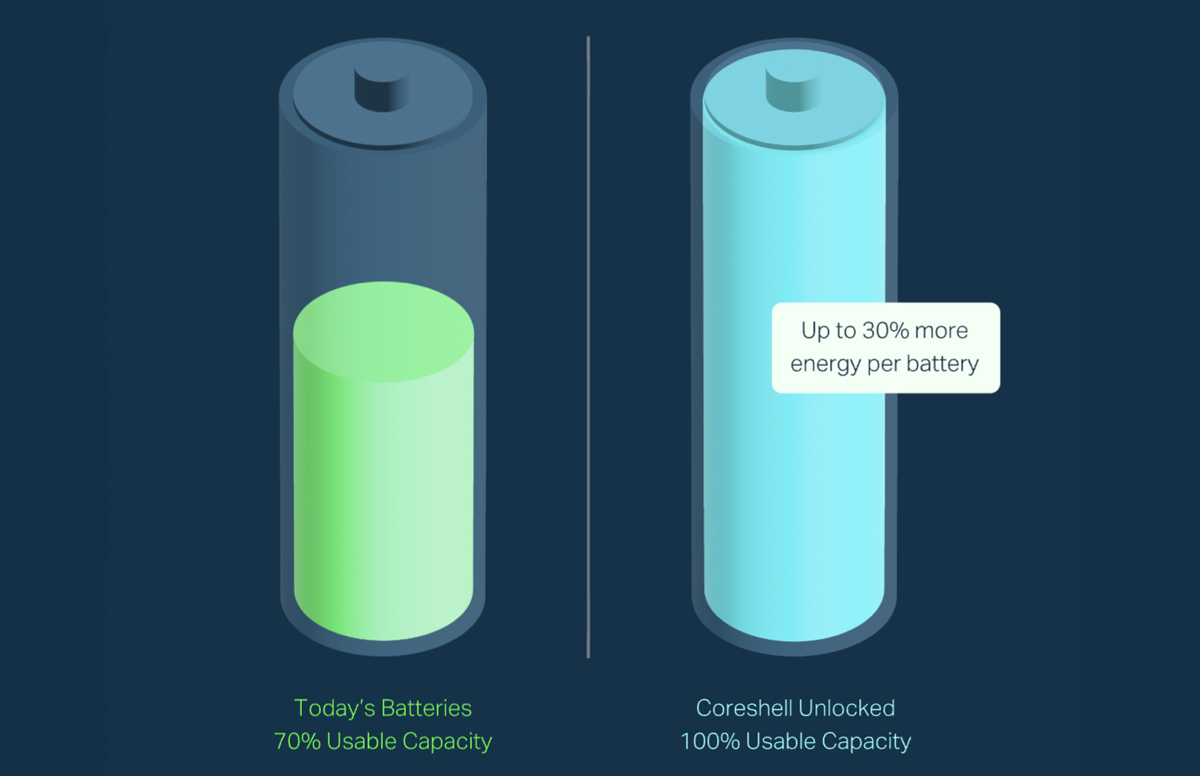

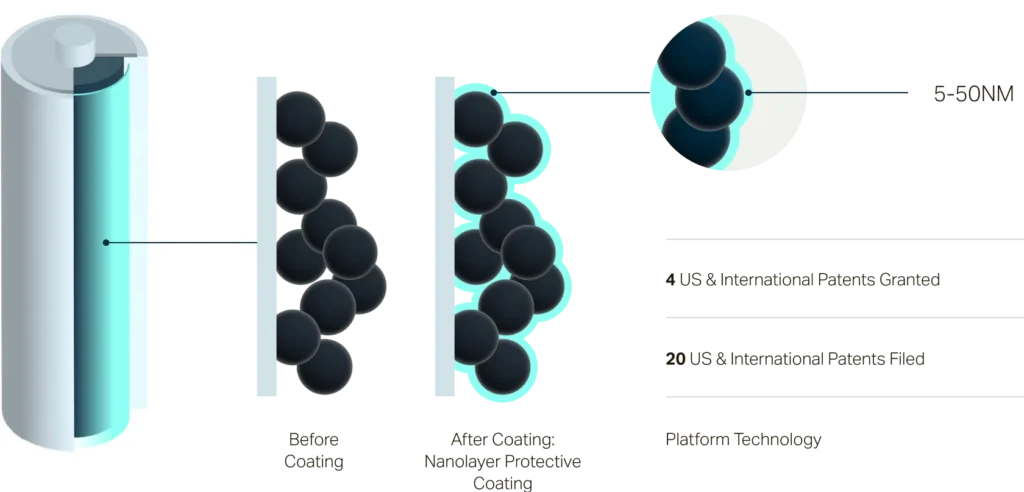

Coreshell says its proprietary battery technology, which features a nanomaterial electrode coating, is the only proven solution to mitigate the degradation of micrometric silicon, preventing its rapid loss of life while still allowing lithium ions to pass through.

Ferroglobe says its proprietary metallurgical purification process produces silicon at purity levels up to 99.995%, and uses no chemical reagent.

According to the companies, these innovations enable the development of lithium-ion batteries with metallurgical silicon-dominant anodes that meet product requirements for cycle life across a range of applications.

“We believe battery-grade, micrometric silicon is the fastest path to decarbonizing the mobility industry,” said Benoist Ollivier, Chief Technology and Innovation Officer at Ferroglobe. “Coreshell has been able to solve the raw metallurgical silicon degradation problem and unlock the true performance of this element.”

“Silicon stores 10 times the energy of graphite, and it is available in sufficient quantity and quality,” said Jonathan Tan, CEO of Coreshell. “It is the only viable pathway to low-cost, long-range EV batteries that can be scaled rapidly using a 100% domestic supply chain. The issue to date is that no one has been able to unlock the power of metallurgical silicon, and the high cost and scaling challenges of highly engineered or silane-based synthetic silicon anodes have prevented the industry from benefiting from its true potential. With Ferroglobe’s silicon and Coreshell’s technology, we have unlocked that power. We are simplifying silicon and stripping out the costs so we can deliver the lowest-cost long-range EV batteries in existence.”

Sources: Ferroglobe, Coreshell