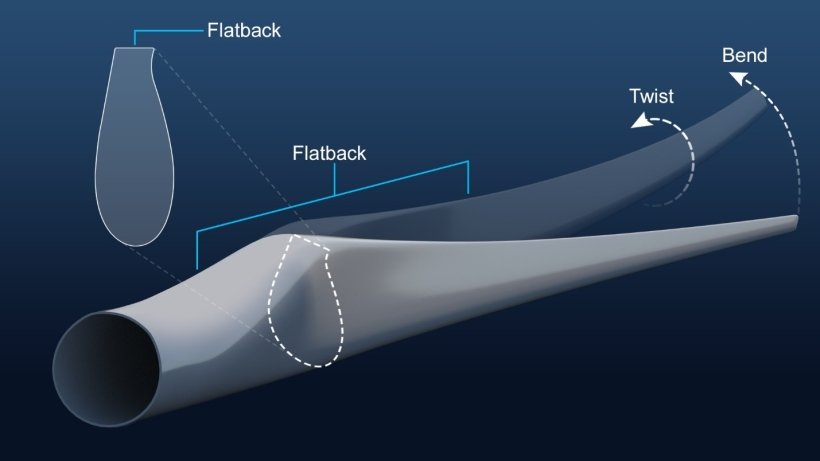

In 2012, two wind turbine blade innovations made wind power a higher performing, more cost-effective, and reliable source of electricity: a blade that can twist while it bends and blade airfoils (the cross-sectional shape of wind turbine blades) with a flat or shortened edge.

The evolution of bend-twist-coupled blades with flatback airfoils represents a story of the U.S. Department of Energy's (DOE) investment and leadership, national laboratory and university research and development, as well as industry collaboration and commercialization. This is also a story of continuous improvement and multidisciplinary problem solving, helping wind energy to become a key player in today's domestic energy mix.

The Challenge of Increasing Energy While Reducing Costs

Before the mid-1990s, wind power was not yet commercially viable because it was still more expensive per kilowatt-hour than energy from conventional electric power plants. The wind industry needed to make improvements that could reliably produce more power per turbine. But finding ways to make such advancements posed challenges.

Wind industry researchers understood that larger rotors with longer blades can capture more energy per turbine, in turn reducing the cost per kilowatt-hour. However, without changes in blade design, the weight and cost and of the longer blade would multiply, thus outweighing the benefits. Additionally, even a small expansion in blade diameter increased wear and tear caused by wind gusts and turbulence.

Competing engineering considerations represented another challenge to the goal of more power at lower cost. Aerodynamic engineers wanted thin shapes from the blade root to the tip to generate as much power as possible. Thinner blades have lower drag and are therefore inherently more efficient for producing power. Structural engineers wanted thicker blade shapes which are structurally more efficient. And manufacturing engineers struggled to control quality when layering fiberglass to support complex shapes with intricate structural requirements.

In the late 1990s, DOE's Wind Energy Technologies Office (WETO) began funding research at Sandia National Laboratories, the National Renewable Energy Laboratory, universities, and manufacturing companies with a focus on cost-effectively increasing rotor diameter and improving efficiency in order to develop wind turbines that could produce more electricity.

Focusing on optimizing wind turbine aerodynamic efficiency, performance, and manufacturing ease, this work examined a broad range of ideas. Among these were bend-twist-coupled wind turbine blades and flatback airfoils, two separate innovations developed in parallel. Both ideas had been mentioned in early studies for aerospace applications but had never been seriously considered for wind turbine applications.

Bend-twist-coupled blades with flatback airfoils reduce wear and allow for longer blades without increasing their weight or cost. DOE investment and leadership, national laboratory and university research and development, and industry collaboration and commercialization made these blades possible.

Graphic by Besiki Kazaishvili, National Renewable Energy Laboratory

Bend-Twist-Coupled Blades

Wind turbine blades naturally bend when pushed by strong winds, but high gusts that bow blades excessively and wind turbulence that flexes blades back and forth reduce their life span.

Bend-twist-coupled blades twist as they bend. As wind forces the blade to flex, twisting changes the blade's angle of attack (the angle at which the blade meets the wind), and thus reduces the load on the blade, decreases stress, and allows for longer blade length without added weight or expense.

Flatback Airfoils

Another innovation that helped reduce blade weight is flatback airfoils, which are easier to manufacture, and enhance structural strength and aerodynamic performance.

The outer half of the blade delivers the bulk of the energy production. The inner half must carry these energy-producing loads to the generator and thus have greater structural demands. An integrated system design using a flatback only for the inner portion of the blade, and thinner airfoils for the outer portion, results in an optimized blade that is lighter, despite being longer.

The shape also leads to manufacturing advantages during production. Without the flatback, the main load-bearing structure within the blade required precise tapering of the composite layers, which added complexity and led to some variability in blade quality. With the flatback airfoil, the main load-bearing structure within the blade could be made as a single component with constant thickness, leading to easier manufacturing. The net result is a longer blade that captures more energy with less material while being easier to manufacture.

Laboratory Testing Leads to Commercial Production

The WETO-funded research progressed from computational analysis to small-scale production. Industry partnerships incorporated the innovations into prototypes that could be evaluated alongside traditional wind turbine blade designs.

Flatback airfoils on wind turbine blades have contributed to estimated energy-cost reductions of nearly 20%.

Graphic by Al Hicks, National Renewable Energy Laboratory

The combination of bend-twist-coupled blades and flatback airfoils enabled wind turbine blades to be made longer, lighter, and cheaper. Evolving from an academic concept to a widely accepted commercial product, bend-twist-coupled blades with flatback airfoils contributed to estimated energy-cost reductions of nearly 20%.

One important and perhaps serendipitous factor that enabled widespread adoption and adaptation of these advances by wind turbine and blade manufacturers is that the technology was not patented. Instead, a record of invention filed with the U.S. Patent Office precluded any one entity from owning the broad concepts exclusively and ensured their availability to the industry in general.

As a result, flatback airfoils have become one of the tools in a wind turbine designer's toolbox. Many modern wind turbine blades from global manufacturers like General Electric, Siemens Gamesa, and Nordex use flatback airfoils based on WETO-funded foundational research. Bend-twist and flatback concepts continue to be design concepts available to all stakeholders.