Modern Control Systems Provide Insights for Power Sector

As power generation embraces digitization, and looks for more reliability and flexibility, the need for advanced instrumentation and control systems grows.

Power plant operators know the importance of maintaining a solid instrumentation and control (I&C) system, one that accurately provides the information needed to ensure the safe and reliable operation of their facility.

It starts with the design of the system, continues with its installation, and then is supported with maintenance that enables continuous, optimal plant performance. Monitoring and regulating the processes involved with power generation facilities is continuously being improved as systems provide real-time data on operating conditions, which enables operators to make better-informed decisions and be proactive when it comes to facility maintenance and more.

Software and hardware that supports I&C processes has become more adaptable, and more user-friendly—important at a time when more power plants are converting to digitization in an industry constantly evolving during the energy transition.

“It’s control that matters,” said John Arnaud, manager of Strategic Accounts and Partnerships at Lumin, an energy management solutions provider. “We need more insight when it comes to controlling loads behind the meter. We are working with utility partners, and helping with residential demand response, with the type of technologies that enable a utility to see those loads.”

A modern, advanced I&C system plays a major role in the profitable operation of a power plant. It supports the maximum availability of a generation facility, whether thermal or renewable—and even battery energy storage—and also supports reliability, flexibility, and operations and maintenance strategies. A good I&C system also can help in maintaining emissions compliance.

The move toward digitization has improved communication between operators and equipment, as software and hardware become more adaptable. That supports the control of equipment as well as support services across a power generation facility.

Lennart Hinrichs, vice president of Partnerships at TWAICE, a battery software platform group, told POWER, “Data forms the foundation for any analytics and optimization case. To use battery storage operators as an example, they can leverage data for predictive analytics to increase the availability of their storage and increase the overall efficiency by anticipating maintenance needs. This preemptive approach with analytics ensures that battery storage systems are not only running smoothly but also prevents costly outages.”

Monitoring Performance

I&C systems are responsible for monitoring and regulating a variety of power plant parameters, including pressure, flow, level, temperature, and overall quality in a facility. Today’s systems provide real-time data on process conditions, which provides operators more insight into plant performance, and enables steps to maintain optimal operation and prevent issues that could result in downtime.

“Efficiency optimization is another critical area for data,” said Hinrichs, who noted the increased importance of I&C when it comes to energy storage, which today often is paired with power generation both at thermal and renewable energy sites. “Analytics platforms provide detailed insights into battery usage and degradation, which enables operators to adjust charging and discharging cycles for optimal efficiency and to minimize wear, thereby preserving the battery’s capacity and prolonging its service life.”

Efficiency and productivity are two focuses of an I&C system, as Hinrichs noted. There is the potential for faster response times to alerts and faults, including through the use of remote monitoring of power generation assets. Engineers working to design I&C systems can utilize advanced control algorithms, data analytics, and other techniques to improve process operations, and support overall plant performance.

Hinrichs told POWER, “Additionally, data analytics can be used to optimize the operational parameters,” helping operators “understand how different usage patterns affect the longevity of their assets and allows them to plan for replacements or upgrades in a cost-effective manner.”

Control at the Factory

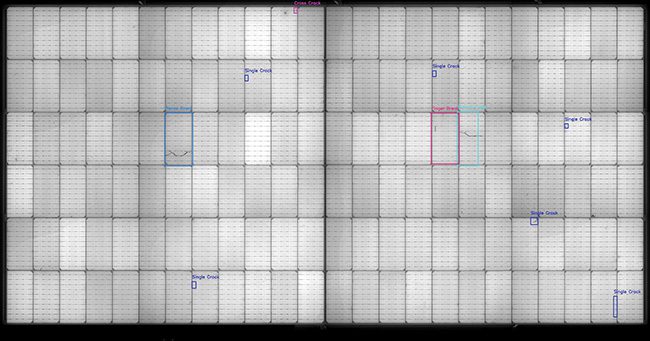

Power generation equipment manufacturers are recognizing how I&C techniques can improve generation assets before they are deployed. Sinovoltaics, a solar power equipment company with headquarters in Hong Kong and Shanghai, China, recently entered the U.S. market with its Sinovoltaics EL Mass Analysis (SELMA) technology, a proprietary electro luminescence (EL) product that uses artificial intelligence (AI) to identify microcracks (Figure 1) and other module defects before equipment is shipped to installers.

|

|

1. Sinovoltaics’ SELMA technology uses artificial intelligence to identify microcracks and other defects in solar modules before they are shipped to installers. Courtesy: Sinovoltaics |

“EL is a process that is part of every solar process, once before lamination, [and] at the end of the manufacturing line, to make sure there are no defects,” said Arthur Claire, head of Technology for Sinovoltaics. “Every manufacturer is doing an EL test at the end of the production line. You would have a picture of each panel, and would have about two seconds to look for defects… a lot of panels with defects that should have been taken out of the production line were being shipped to clients.”

With Sinovoltaics’ process, Claire said, “we can calibrate the machines, [and have] thousands of pictures related to each module. We can analyze with SELMA, and check to see whether it agrees with quality standards. We can find and reject those modules before they get shipped.” Claire, who spoke with POWER at the InterSolar event in San Diego, California, in January, said it gives solar equipment manufacturers another level of control when it comes to their products.

Claire said that “today in the U.S., it’s really common for companies that purchase from Southeast Asia and other countries to do sampling. They may go to the factory and monitor the manufacturing line—do pre-shipment inspections. But how many modules are you supposed to inspect? Sinovoltaics’ software inspects every single one, as opposed to sampling. I’m pretty comfortable saying we are the company inspecting the most modules in the world today.”

Claire continued: “Module manufacturing is a volume business, most of it done by robots. Factories need quality standards to define whether [the product] is good or not. We have tremendous experience in Asia, and we have U.S. companies asking us to come to their factories to help with their manufacturing process.”

Maintenance and Reliability

Engineers involved in the design of I&C systems recognize the importance of monitoring equipment, including enabling of proactive maintenance to make timely repairs and minimize downtime. The economics of today’s power generation put a premium on availability and reliability.

|

|

2. Utilities are creating centralized, remote operation collaboration centers to optimize resources and improve performance. The use of integrated control, monitoring, and analytics provides insights that can detect anomalies, enabling the control system or an operator to take action. Courtesy: Emerson |

Rick Kephart, vice president of Technology for Emerson, told POWER that when looking at equipment monitoring, particularly remote monitoring, “The key factors are less about suitable situations and more about delivering insights, actionable intelligence, and results to the right personas. For issues that might be sudden or catastrophic, teams need somebody nearby who can intervene. That can mean a control operator who is stationed onsite, but it can also mean prioritizing data delivery so an operator in a remote control center [Figure 2] has the information they need when they need it.”

Distributed power generation, including increased interaction between utilities and their customers at the residential level, has produced a need for I&C systems to facilitate that communication. Lumin, which provides hardware and software solutions in that space, recently unveiled its newest residential load control platform, Lumin Edge. Arnaud spoke with POWER at InterSolar about how the product merges Lumin’s intelligent load management software with a modular design, providing the system with new functionality. The Lumin Edge pre-release program, in which the company recently shipped units to co-op and investor-owned utilities across the U.S. and Canada, focuses on grid services such as high-resolution, behind-the-meter analytics, and advanced demand-side management tools.

“Control is one thing, but being able to provide insights to the customer through the Lumin app also is important,” said Arnaud. “Then there are the insights the utility would gain, particularly at a granular level—what appliances are being turned on, who is charging an EV—it’ll be really interesting as we’re working with a lot of utility companies. And customers can opt-in or opt-out of demand response.”

Arnaud said the push toward electrification means utilities are facing more pressure to maintain grid stability. The Lumin Edge provides behind-the-meter analytics and offers real-time load management capabilities, which are meant to help grid operators shape demand with more precision. It also allows electricity customers more insight into increasingly complex utility rate structures. The modular design of the Lumin Edge Controller means it can be placed anywhere along the wire, from a home’s service panel to a targeted appliance. The controllers communicate wirelessly with the Edge Hub through a secure mesh network. “The customer gets really cool technology, and access to a lot of utility programs with incentives,” said Arnaud.

Recognizing Cyber Threats

Cybersecurity is receiving more attention as an integral part of I&C systems. Chris Stangl, managing director of Berkeley Research Group’s Cybersecurity and Investigations practice, told POWER, “Ideally, this should be a strategic business decision informed by a thorough risk assessment. Before introducing new technology, it is crucial to conduct an assessment to determine the probability of a threat actor exploiting a potential vulnerability in the technical implementation.”

Stangl, who spent more than 20 years as an FBI Special Agent in the agency’s Cyber Division, including as a member of the Senior Executive Service, has investigated a broad range of cyber cases including hacking by both cybercriminals and nation-state actors, and has addressed counterintelligence and insider threats.

“In the event of a successful attack, the assessment should evaluate the potential impact on the confidentiality, integrity, or availability of information and resources,” said Stangl. “Particularly in the realm of operational technology and industrial control systems [ICSs], where there is potential for repercussions on public safety or national security, a risk assessment is imperative. The results of such an assessment should be methodically considered when contemplating the implementation of remote monitoring.”

Stangl continued: “When considering connecting legacy ICSs, originally designed to be isolated, to the Internet, special attention is warranted. This includes a comprehensive understanding of associated risks, a well-funded program to safeguard these critical assets, continuous monitoring, and a meticulously documented and practiced response plan.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).