In First, NRC Approves Nuclear Fuel Fabrication Enriched up to 8% for Commercial Power Generation

The Nuclear Regulatory Commission (NRC) has granted Global Nuclear Fuel—Americas (GNF) the regulatory body’s first-ever authorization to produce nuclear fuel with uranium-235 (U-235) enrichments up to 8% for commercial power generation.

GNF, GE Vernova’s nuclear fuel arm, on Feb. 15 said the NRC approved a license amendment that will allow its nuclear fuel fabrication facility located near Wilmington, North Carolina, to produce the special nuclear fuel (SNF) material, also known as low enriched uranium plus (LEU+). The fuel facility’s previous SNM–1097 license allowed GNF to possess and use U-235 enriched up to 5% for commercial nuclear power fuel fabrication.

The NRC last year issued a certificate of compliance that will allow GNF to ship nuclear fuel bundles of up to 8% using GNF’s RAJ-II shipping container, a specialized package designed to transport boiling water reactor (BWR) fuel assemblies. In addition, “NRC has also approved licensing topical reports for advanced nuclear methods that enable GNF to analyze fuel with enrichments greater than 5 weight percent,” GNF noted on Wednesday.

“These regulatory milestones build on our long history of designing and fabricating fuel for the nuclear industry,” said GNF executive vice president, Mike Chilton.

A Major Milestone for Higher Enrichment Fuel

The NRC’s first approval for fuel fabrications with enrichments up to 8 weight % U-235 for use in commercial power production marks a significant milestone for the nuclear sector, which has been working to implement higher-enrichment fuels. “Higher enrichment fuels are anticipated to improve nuclear fuel cycle economics, including through power uprates for existing boiling water reactors and also for the next generation of reactor technology, including advanced and small modular reactors,” GNF noted Wednesday.

Nuclear fuel enrichment generally falls into three “buckets” that describe a range for the percent composition of the isotope of U-235: low-enriched uranium (LEU), high-assay low-enriched uranium (HALEU), and LEU+, and high-enriched uranium (HEU).

The nuclear energy industry has traditionally operated with LEU, uranium enriched to 5 weight %. LEU dominates the industrial supply chain and regulatory frameworks, while HALEU describes a nuclear material enrichment range spanning from 5 weight % to 19.75%. LEU+ generally describes a range of between 5% to 10 weight %. HEU enriched above 20% is typically used in research and test reactors and by the U.S. Navy. Several advanced reactor technologies, including gas-cooled, liquid metal, or molten salt designs, will require LEU+ at 6% or HALEU at 19.75%.

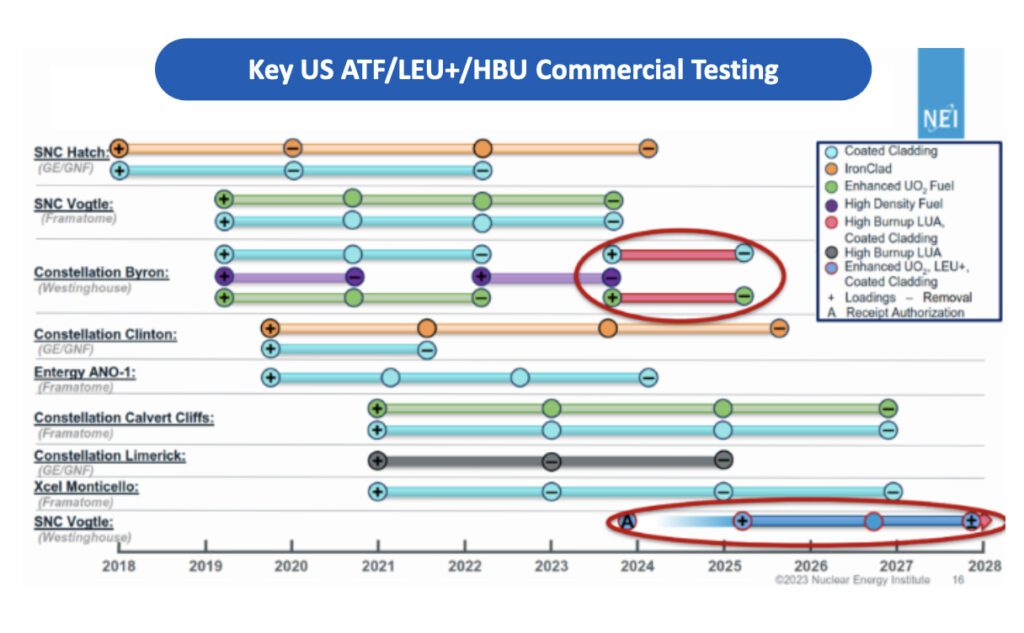

Since 2018, bolstered by the U.S. Department of Energy (DOE), the nuclear industry has also made steady progress in implementing accident-tolerant fuels (ATF). The new technologies in the form of new cladding and/or fuel pellet designs can be paired with fuel enrichments of up to 10% (LEU+) to increase operational flexibility, longer fuel cycles, and support power uprates. A recent Nuclear Energy Industry (NEI) baseline survey of 19 NEI member companies that operate 80 commercial power reactors in the U.S. suggests at least 20 sites have expressed “varying levels of interest/planning” for ATF.

For now, the first ATF lead test assemblies (LTAs) with a weight greater than 5% are slated to be loaded in 2025 at Southern Co.’s Plant Vogtle Unit 2. Southern Nuclear, Southern Co.’s nuclear arm, has told POWER the assemblies will couple Westinghouse’s High Energy Fuel initiative and the EnCore Fuel program. The fuel will feature enrichments up to 6%. Assemblies will contain “ADOPT uranium dioxide pellets, AXIOM fuel rod cladding, and chromium-coated cladding combined with Westinghouse’s advanced PRIME fuel assembly design,” Southern Nuclear noted.

Southern Nuclear in September 2023 received the NRC’s first-of-a-kind approval for the use of ATF fuel. The significant milestone makes Vogtle 2 the first U.S. power reactor authorized to operate ATF fuel rods to burnup levels exceeding the current regulatory limits.

Fuel Fabrication Developments

While GNF now has approval to manufacture, ship, and analyze nuclear fuel performance with enrichments of up to 8 weight %, the NRC is reviewing two other fuel fabrication submittals seeking higher enrichments, an NRC spokesman said. In November 2022, the NRC accepted X-energy’s TRISO-X license application to allow it to build and operate a new fuel fabrication facility in Oak Ridge, Tennessee. The NRC intends to complete its review by June 2025 at a cost of $4.9 million.

TRISO-X broke ground on the fuel fabrication facility in October 2022 and is expected to be commissioned in 2025. X-energy anticipates the facility’s produced tri-structural isotropic (TRISO) particle fuel, which will use HALEU, will support its Xe-100 reactor design.

X-energy is slated to demonstrate a proposed four-unit 320-MWe Xe-100 advanced nuclear reactor facility at a Dow chemical materials manufacturing site in Seadrift, Calhoun County, Texas. X-energy is now working to submit a construction permit for that project, which is part of the DOE’s Advanced Reactor Demonstration Program (ARDP). Construction on the four-reactor project is expected to begin in 2026 and to be completed by the end of this decade.

At an NRC commissioners’ briefing on Dec. 12, 2023, GNF LWR Fuel Product Director Rich Augi noted that along with license amendments sought by Southern Nuclear and Constellation, GNF, Framatome, and Westinghouse have also been proceeding in license submittals. “Each vendor has submitted [a] fresh fuel shipping container. I believe all three have now received their license there for higher enrichment,” he said.

GNF Has Started Process to License HALEU Fabrication Facility

GNF, meanwhile, continues to pursue innovation under its advanced fuel program, Augi said. “We’ve been pushing to develop new technologies like our armor-coated cladding and advanced materials research to provide accident tolerant benefit,” he said. “We’ve been successful in installing and operating lead test assemblies of both ARMOR and IronClad, our iron, chrome, and aluminum cladding at [Southern Co.’s] Plant Hatch and [Constellation’s] Clinton Power Station, and have successfully transported irradiated material from the reactor site to the Oak Ridge National Lab.”

The early installations will “provide key performance information needed to drive technologies to industrial application. And with the development and licensing of advanced methods and materials, GNF is embarking on developing the next generation of fuel product,” he said.

Looking ahead, GNF plans to expand its advanced fuel manufacturing capabilities by potentially building out a supply chain for advanced reactors. In October 2022, TerraPower and GE Hitachi Nuclear Energy (GEH) announced they would build a fuel fabrication facility at GNF’s Wilmington facility to create reliable fuel for the 345-MWe Natrium pool-type sodium fast reactor (SFR) demonstration in Wyoming and future Natrium plants. Construction of the first Natrium power plant, slated to begin in 2023, was recently delayed to 2025, given a lack of HALEU.

The Natrium fuel facility will be jointly funded by TerraPower and the U.S. DOE through the ARDP, Augi said. It “represents an investment of more than $200 million into advanced fuel fabrication,” he noted.

GNF has already kicked off a process to license the standalone Category II fuel fabrication facility. After GNF expressed intent to submit a license amendment request (LAR) for the HALEU (at up to 20 weight %) fabrication facility in October 2021, in March 2023, the NRC granted it an exemption to submit the LAR in two parts. While GNF submitted the first part—a supplemental environmental report–in March, it told the NRC in July 2023 that the complete LAR would be delayed about two years. GNF is now anticipated to submit the full LAR in the third quarter of 2025, the NRC recently reported.

GEH’s 300-MW BWRX-300, meanwhile, will use a GNF2, a “proven” nuclear fuel assembly, Augi noted. Ontario Power Generation (OPG) is developing the world’s first BWRX-300 project at its Darlington New Nuclear Project site east of Darlington Station in Bowmanville, Ontario, and expects it could be ready for commercial operation in 2029.

OPG in November 2023 unveiled four contracts to ensure a fuel supply for the first SMR of its four-unit plant at Darlington. Contractors include Cameco, which will supply natural uranium hexafluoride (UF6) from a conversion facility in Port Hope, Ontario. Urenco USA will provide uranium enrichment services from its operations in Eunice, New Mexico, while French nuclear fuel firm Orano will provide additional Enriched Uranium Product (EUP) from their operations in France. GNF will provide fuel fabrication and related technical services and fuel assemblies.

“Most importantly, we have a proven nuclear fuel in the GNF2 product. We’ve delivered more than 25,000 bundles to the fleet. It’s been utilized in more than 70% of the BWR fleet. We’ve fabricated it both in U.S. and in Europe, [it] has an existing supply chain, and does not require HALEU. It can be operated with LEU up to 5% enriched fuel,” Augi noted. “Qualified fuel is significant because it can take 10 years to qualify a new fuel type. This does give us an advantage we feel.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Updated (Feb. 16): Adds clarifications and details about OPG’s recent fuel supply contracts.