A circular economy for electric vehicle batteries appears to be still some way off, but metal recycling expert EMR claims to be making inroads, and to be helping shape the future of the sector.

The roll out of electric vehicles (EVs) – and the sophisticated high-power batteries on which they run – represents a moment of profound change for both metal recyclers and their partners in the UK automotive industry.

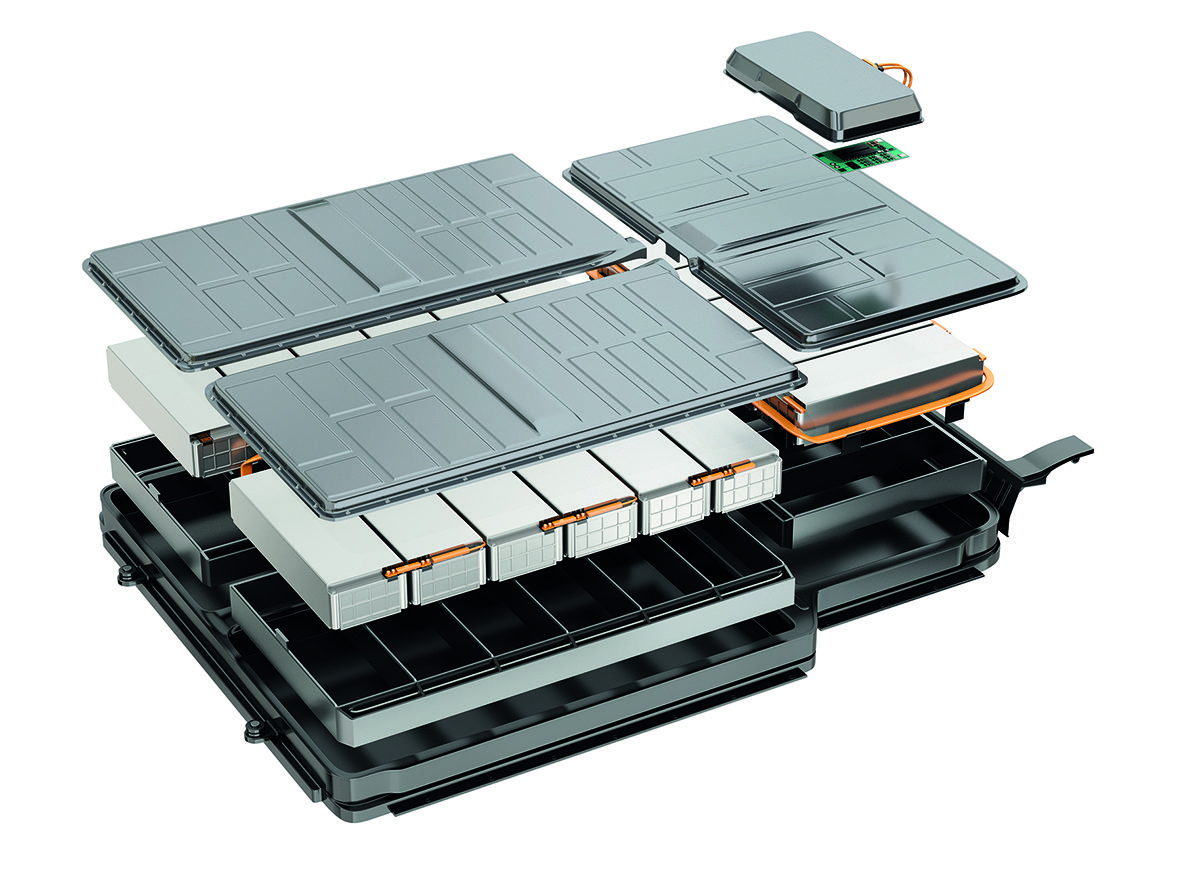

At stake is the possibility of a truly circular economy for EV batteries, boosting the sustainability of the technology, while safeguarding the valuable resources – including lithium, cobalt, and nickel – on which it relies.

“It took four decades to perfect the processes for recycling an internal combustion engine (ICE) vehicle, but this time we will only have a few years to get it right,” says Helen Waters, Head of Electric Battery Recycling at EMR. “Some of the processes are the same, but many aren’t – from efficiently testing the health of a battery to disassembly and logistics, there’s a number of challenges that EMR has identified in creating this new circular economy and we’re already busy speaking to car makers, leasing companies and dealerships to get it right.”

EMR recycles thousands of end-of-life vehicles (ELVs) every week at its more than 60 UK sites. As EVs become more common on our roads, the firm hopes to maintain a market-leading position as a sustainable, responsible, and efficient recycler of ELVs.

Yet, the current generation of high-performance EVs are so reliable, they say, that most will not reach the end of their working lives for at least a decade or more. That’s why EMR says it is now working with the automotive industry, using product recalls, warranty failures and even the batteries used in e-bikes and e-scooters to provide the volume of material needed to help scale up a circular economy for EV batteries.

“Our message to the industry is to work with us today so that our businesses can collaborate, whether that is on designing new easy-to-recycle batteries, putting in place the logistics required for this transition or to further develop the technology required to recycle EV batteries,” says Helen.

A lot of this work is already underway. Over the past two years, EMR has led a project aimed at separating and processing end-of-life EV batteries for re-use or remanufacturing (for renewable energy storage) and, if this isn’t possible, recycling. The RECOVAS consortium brings together car makers, including Bentley, Jaguar Land Rover, and BMW, alongside Connected Energy, Autocraft Solutions, the UK Battery Innovation Centre (UKBIC) and academics from the University of Warwick – an example of the sector-wide cooperation that that will be required going forward. The collaboration is part-funded by the UK’s Advanced Propulsion Centre.

Waters says she has also “been in conversation with OEMs about ways to improve cars from the design phase onwards, to improve the process of recycling or re-using their batteries at end of life.

“Automotive manufacturers have their own 2030 sustainability targets in place, and many have already pledged to deliver a circular economy for their materials as well. In addition, EU Recycled Content targets – added to concerns about resource security – means the industry is already aware that business as usual is no longer an option.”