This article contains paid for content produced in collaboration with SEEPEX.

Thames Water owns and operates Basingstoke Sewage Treatment Works. This regional sludge treatment centre processes sludge from various locations in either liquid or cake form. The Basingstoke Sludge Treatment Centre (STC) houses advanced facilities, including thermal hydrolysis and anaerobic digestion plants, capable of processing 53tDS/day of sludge from Basingstoke, Farnham, Fleet, Guilford, and Newbury. The site now generates enough energy from waste to power itself and export to the national grid.

Problematic pulper feed pumps

The pulper feed pumps from another supplier were experiencing stator failures every four months, which caused breaks in the processing of the sludge, leading to reduced energy production and time-consuming, costly repairs. Thames Water approached SEEPEX with the task to offer a more reliable pump, capable of efficiently transferring up to 30 m3/hr of 6-10%DS high-temperature sludge.

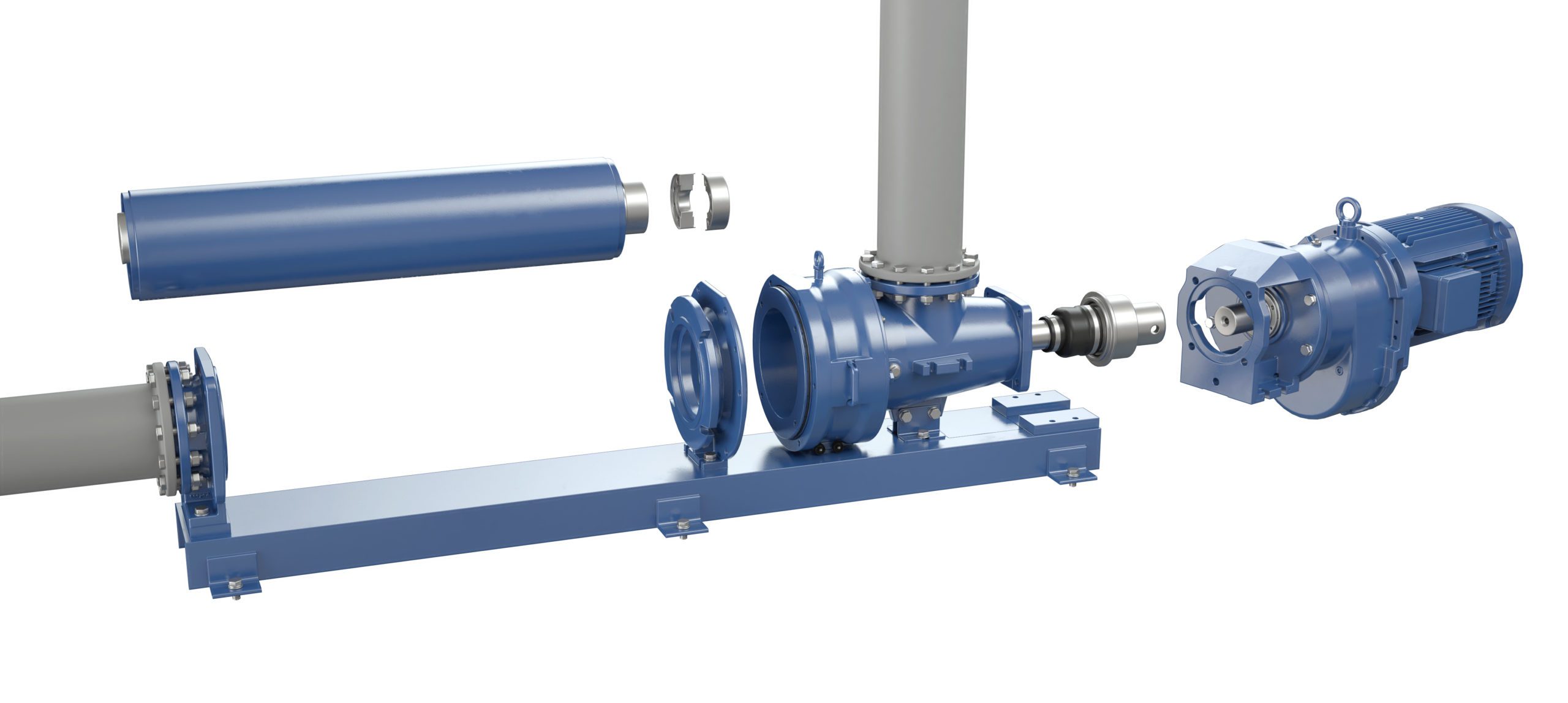

Following detailed discussions with the on-site process engineers and maintenance manager, SEEPEX selected its BNM pump – fitted with smart maintenance solutions, and also incorporated its advanced digital monitoring package.

Simple maintenance for big pumps

The SEEPEX BNM maintain-in-place pump range is designed to make maintenance for large and challenging-to-maintain pumps simple. By leveraging innovative design features, maintenance time is significantly reduced, up to 80%. Fast and straightforward maintenance of pump components ensures streamlined preventative inspections and improves operational reliability and service life, effectively eliminating unscheduled downtime.

Invaluable insights with digital solutions

Since its installation, the BNM pump with integrated pump monitoring, has been operating 24/7 without requiring any service intervention. Real-time data collected through the monitoring sensors has allowed SEEPEX to provide the site with invaluable, real-time information on the pumps performance. Any deviation from the pumps design parameters triggered an investigation.

This proactive approach highlighted fluctuations in the sludge temperature and the time of day these fluctuations occurred. Analysis of the data by SEEPEX enabled the correct rotor/stator combination to be selected which will again reduce the downtime of this asset even more.

Adapting innovation empowers efficiency

The incorporation of SEEPEX innovative pump solution with monitoring capabilities has enabled Thames Water’s Basingstoke to benefit from reduced downtime and cost savings. The elimination of frequent stator failures and prompt detection of potential issues drastically increased uptime, maximising operational efficiency while the streamlined maintenance process has reduced spend on costly spares, ensuring cost-effectiveness and improved overall financial performance.

As the Basingstoke Sewage Treatment Works continues to set new benchmarks in sustainability and efficiency, the collaboration between Thames Water and SEEPEX serves as a glowing example of how cutting-edge technology and expertise can drive positive change in the wastewater industry.

Improve your efficiency like Thames Water’s success story. Contact SEEPEX today to unlock innovative pump solutions designed for the water and wastewater industry to solve your unique pumping challenges.