Sealing technology firm KACO has introduced the second generation of its structured mechanical seals for internal rotor cooling.

“Following the successful market launch of the first generation of mechanical seals for internal rotor cooling, KACO has significantly improved these systems by consistently optimizing the microstructures in terms of occurring power losses,” says the company, which used CFD simulations to redevelop the microstructuring of the seals.

“By consistently balancing simulation and testing, we have succeeded after less than a year in reducing friction losses to almost a third and at the same time, depending on the seal size, in reducing the technical leakage occurring in some test cycles to a level that can no longer be measured,” says VP of Research and Development at KACO Andreas Genesius.

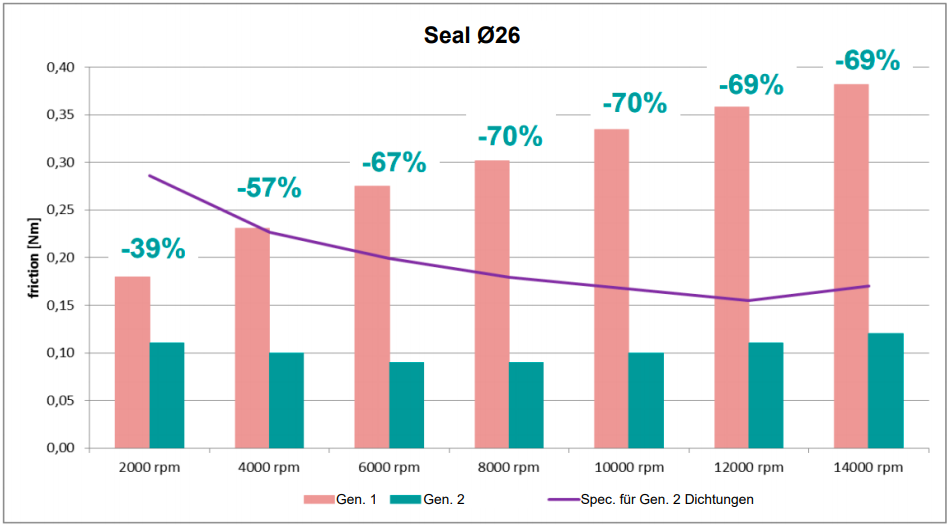

KACO says the second-generation seal “shows potential savings in power losses of 50-70% compared to the current state of the art in series production.”

“The significant savings in power losses at the sealing system create a new attractiveness of direct internal rotor cooling in terms of range optimization of the vehicle,” says KACO.

Source: KACO