Turbocharging Production Cycles: Unlocking the Speed of Innovation

May 17, 2024In the relentless race of modern commerce, the imperative to swiftly deliver products to market is more pressing than ever. The velocity of production cycles not only dictates competitiveness but also underpins the capacity to innovate rapidly. In this discourse, we delve into an array of strategies aimed at expediting production cycles, with a keen focus on harnessing the potential of rapid prototyping services, refining operational processes, embracing cutting-edge technologies, and fostering a culture of nimbleness.

Unleashing the Potential of Rapid Prototyping Services

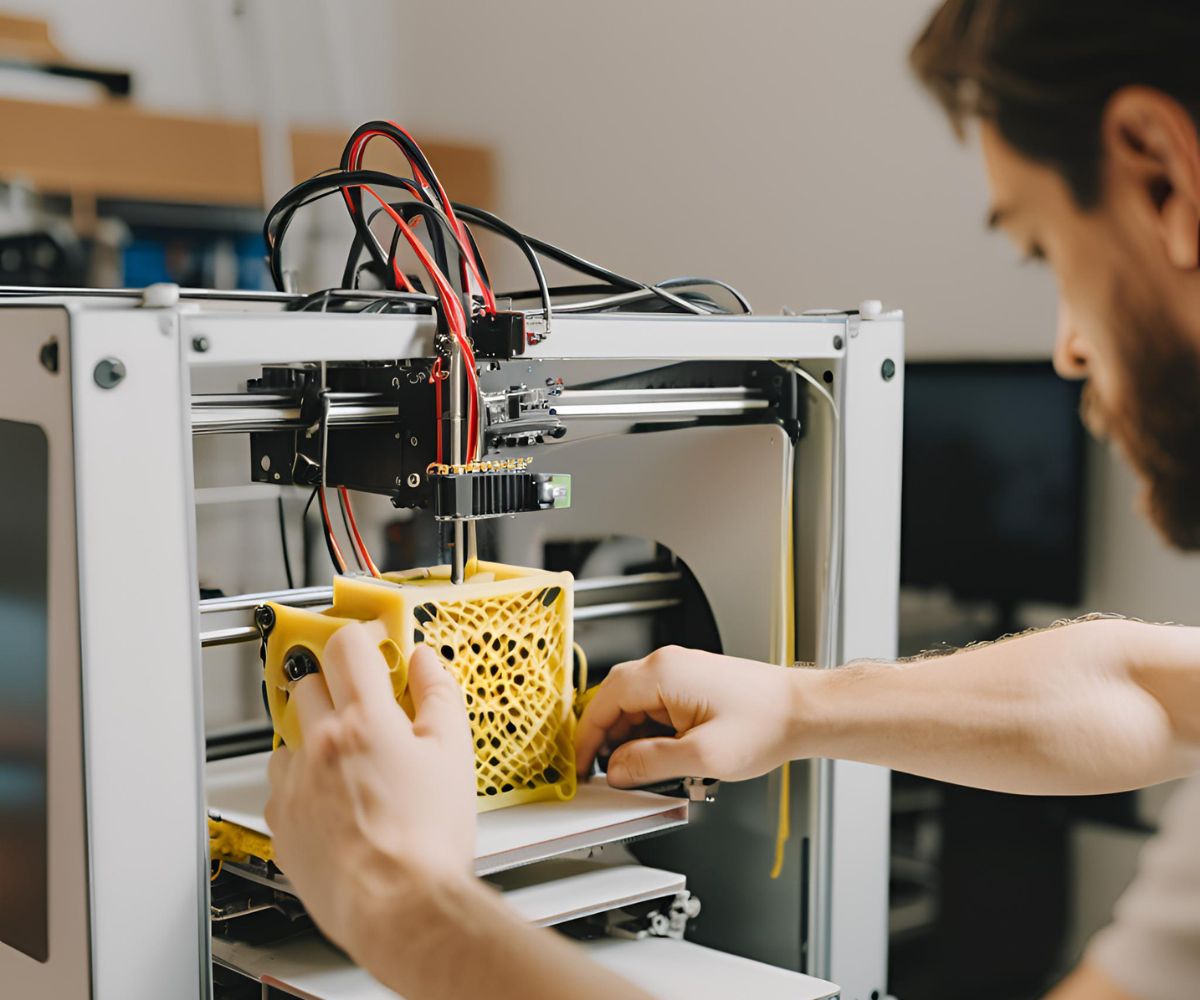

The advent of rapid prototyping has redefined the paradigm of product development, facilitating the swift creation of tangible prototypes from conceptual designs. Engaging with rapid prototyping services empowers businesses to compress the timeline from ideation to prototype, thanks to the utilization of advanced technologies like 3D printing, CNC machining, and injection molding. Leveraging Rapid PSI rapid prototyping services enables businesses to swiftly iterate designs and validate concepts, expediting the journey from ideation to tangible prototypes.

Beyond mere expediency, the benefits of rapid prototyping services extend to:

- Agile Iteration: Enabling rapid adjustments and refinements to designs based on real-world feedback, thereby truncating the development phase.

- Early Validation: Facilitating the validation of concepts through the creation of physical prototypes at the nascent stages, mitigating the risk of costly flaws surfacing later in the process.

- Cost Efficiency: Minimizing expenditure by circumventing the overheads associated with traditional prototyping methods, such as tooling expenses, while averting potential design pitfalls.

Embracing rapid prototyping services thus emerges as a cornerstone strategy in the quest for accelerated production cycles.

Refining Operational Processes

The streamlining of operational workflows constitutes a pivotal avenue for curtailing lead times and enhancing operational efficiency. This endeavor involves a meticulous examination of existing processes to identify bottlenecks, excise superfluous steps, and optimize workflows for seamless operations. Key tactics encompass:

- Value Stream Mapping: Conducting a comprehensive audit of the production pipeline to pinpoint inefficiencies and areas ripe for improvement.

- Just-in-Time Manufacturing: Embracing lean principles to minimize inventory overheads and expedite production by manufacturing goods in alignment with demand.

- Automation: Deploying automated systems and robotics to streamline repetitive tasks, augment throughput, and elevate overall productivity.

- Cross-Functional Collaboration: Fostering synergistic collaboration across disparate departments, such as engineering, manufacturing, and supply chain, to foster cohesion and expedite decision-making.

Embracing Cutting-Edge Technologies

Technological prowess serves as a potent catalyst in propelling production cycles towards swifter trajectories, bolstering efficiency, precision, and adaptability. Enterprises can leverage an array of technological innovations to streamline operations and catalyze innovation:

- Digital Twins: Harnessing the power of digital twin technology to create virtual replicas of physical assets, enabling predictive modeling, iterative testing, and optimization of processes.

- Internet of Things (IoT): Leveraging IoT devices to glean real-time data from manufacturing equipment, facilitating predictive maintenance, performance monitoring, and optimized production scheduling.

- Cloud Computing: Embracing cloud-based software solutions for collaborative design, data storage, and analytics, fostering seamless collaboration and accessibility.

- Artificial Intelligence (AI): Employing AI algorithms for predictive analytics, quality assurance, and demand forecasting, empowering data-driven decision-making and process optimization.

Cultivating a Culture of Agility

At the heart of expeditious innovation lies a culture characterized by agility, where adaptability, experimentation, and continuous improvement reign supreme. Cultivating such a culture entails:

- Encouraging Risk-Taking: Nurturing an environment where calculated risk-taking is encouraged, fostering a spirit of innovation and exploration.

- Iterative Learning: Instilling a mindset of perpetual learning and refinement, wherein setbacks are perceived as stepping stones towards progress and innovation.

- Agile Methodologies: Embracing agile frameworks such as Scrum or Kanban to manage projects, prioritize tasks, and pivot swiftly in response to evolving requirements.

- Leadership Advocacy: When you promote leadership within your teams, you are championing agility by allowing other people to step up and take control, as they might spot areas that you have not noticed that can be improved. This can lead to new innovations, and if you show that you believe in your teams and their leadership qualities, you will have a higher retention rate, particularly if you invest in their development through training programs.

Conclusion

In the dynamic crucible of contemporary commerce, the ability to accelerate production cycles constitutes a linchpin for sustained success. By harnessing the potential of rapid prototyping services, refining operational processes, embracing cutting-edge technologies, and fostering a culture of agility, enterprises can navigate the labyrinth of innovation with unparalleled alacrity. Through the diligent implementation of these strategies, businesses can not only expedite time-to-market but also engender a culture of efficiency, resilience, and innovation, propelling them towards unrivaled competitiveness in an ever-evolving marketplace.

HFN News is your leading source for fresh hydrogen and renewable energy updates. Amid the fast-paced growth of hydrogen companies, we provide top-notch news and insights about this exciting sector. Our coverage spans from hydrogen cars to global sustainable initiatives, and we highlight the latest in green jobs and developing hydrogen hubs. We invite you to share your local hydrogen news and explore today’s renewable energy job listings on our site. Thanks for choosing HFN News as your trusted guide to the hydrogen and renewable energy world!

HFN News is your leading source for fresh hydrogen and renewable energy updates. Amid the fast-paced growth of hydrogen companies, we provide top-notch news and insights about this exciting sector. Our coverage spans from hydrogen cars to global sustainable initiatives, and we highlight the latest in green jobs and developing hydrogen hubs. We invite you to share your local hydrogen news and explore today’s renewable energy job listings on our site. Thanks for choosing HFN News as your trusted guide to the hydrogen and renewable energy world!