The diversity of electric motors used in today’s EVs is quite striking. Motor-makers have a huge range of choices, from materials to rotor and stator designs, and they’ve explored many different possibilities. In April, teardown specialist Sandy Munro analyzed 10 leading EV motors and developed a comprehensive side-by-side comparison report.

Designing a motor involves trade-offs among size, efficiency, and power. Munro praised the motors found in Tesla’s Model 3 and Model Y for achieving a good balance among these three parameters. Some were shocked when Tesla switched from using an induction motor (a design originally invented by the company’s namesake, Nikola Tesla) in Models S and X to using a permanent magnet motor in Models 3 and Y, but the choice seems to have been the right one.

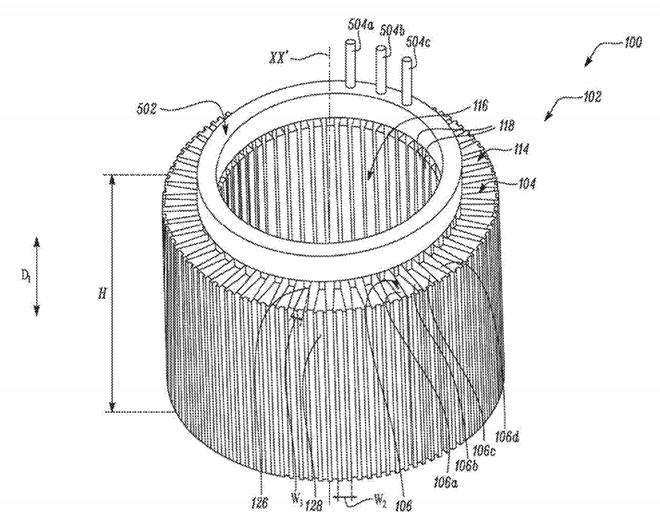

The innovative automaker’s quest to improve its products is ongoing, and it recently published a patent for a new type of stator.

Tesla’s patent application, Stator for an Electric Motor, reads, in part:

An example stator includes a stator core having teeth that are radially arranged about a common central axis of the stator and located in a spaced apart manner from one another. Each tooth has an inward portion and an outward portion. The example stator further includes an electrically transmissive coil of wire that is wound contiguously upon the inward portions of at least a subset of teeth from the plurality of teeth. The stator also includes wedge members that are radially arranged about the common central axis and located intermittently with the plurality of teeth such that each wedge member abuts with the outward portions of adjacently located teeth.

Fascinating reading for electrical engineers. For the benefit of those with more moderate technical skills, the patent application teased out the benefits Tesla hopes to realize from the new design:

Typical electric motors have stator cores that are formed from metal laminates stacked one above another. An inner periphery of these stator cores typically define slots (or teeth) on which multiple coils of wire are wound. Each coil of wire may be wound over all or a subset of the slots. As the slots are defined only along the inner periphery of the stator core, such winding of the coil of wires over the subset of slots in the stator core may be challenging, laborious and hence, time consuming. Moreover, such winding may incur additional expense in terms of tooling requirements that are required to perform the winding of coils in the slots of the stator core.

Presumably, Tesla’s new stator design mitigates these issues, making the motor easier to assemble, and hence, cheaper.

For some more edifying details about stators and rotors, see Jeffrey Jenkins’s article, Specialized motor materials and constructions, part one and part two, which appeared in the March/April and May/June issues of Charged.

SEE ALSO: Charged interviews with Tesla’s chief motor engineer:

- Tesla’s chief motor engineer discusses the potential of next-generation motor technologies

- Tesla’s lead motor engineer why modeling and optimization is so vital to its design process

- Designing a permanent magnet machine for Tesla’s Model 3

Source: FreePatentsOnline via Tesmanian