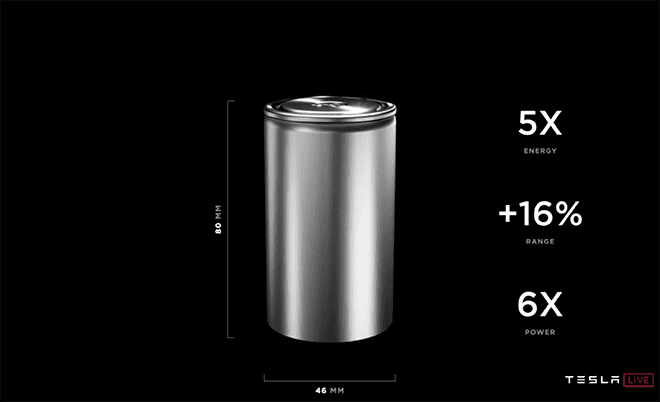

When Tesla unveiled its new 4680 battery cell at last September’s Battery Day event, it described the new cell as a “massive breakthrough” that could enable the production of a new generation of much cheaper EVs. Tesla is believed to be producing the cells on a pilot line at its Fremont plant, but is also working with battery suppliers. Panasonic and LG have both accepted the invitation to the party.

However, some industry experts see difficulties on the way to mass-producing the new cells. “There are significant technological issues to get past, issues that many in the industry have been trying to tackle for years,” Wood Mackenzie Analyst Ram Chandrasekaran told Bloomberg. “If achievable, these battery cells would be groundbreaking. But the jury’s still out on whether they’re deliverable.”

Panasonic says it can get the job done, and is currently working on a prototype production line.

“Producing these larger cells requires you raise your craftsmanship one or two full levels or there will be safety issues,” Yasuaki Takamoto, Panasonic’s EV battery head, told Bloomberg, and added that his company’s proven safety systems “absolutely give us an upper hand here.”

Many of the advantages of the new 4680 cells compared to the 18650 and 2170 cells Tesla is currently using have to do their larger size, which would reduce the need for components used to connect individual cells. The larger capacity, however, may also make the cells more difficult to produce. They are prone to overheating, because it’s difficult to disperse heat from their center, and are also more susceptible to particle contamination, which can cause a short circuit leading to a fire, Takamoto explained.

Compared to other EV battery producers, Panasonic has been building scale more slowly, expanding production only at a pace at which it can maintain safety standards. The company has been mass-producing Li-ion EV batteries since 2010, and currently produces some 2.5 billion cells a year without major safety issues, and Takamoto believes it will have a competitive advantage in producing the 4680 cells.

Elon Musk acknowledged the difficulty of mass-producing the 4680 cells in a speech at a battery conference last November. Tesla had produced the new cell at a “bench-top level” and was working to progress to “pilot-plant level,” but “scaling up the production process is much harder than proving something out on a lab bench.”

“Working with a partner like Panasonic that has extensive experience in large-scale cell manufacturing will boost the likelihood of Tesla achieving the targets the company outlined at its Battery Day event,” wrote BloombergNEF analyst James Frith.

Source: Bloomberg