The buildings sector is responsible for about 40 percent of global greenhouse gas emissions, and building materials are a big part of the problem. Steel and concrete account for 21 percent of total emissions and are primarily used in the built environment, according to Architecture 2030.

What, then, if we could turbocharge wood to replace these emissions-heavy materials? And reduce plastic waste, while we’re at it?

InventWood, a Greentown Labs member and Healthy Buildings Challenge participant, begins with regular wood and then modifies its lignin content (think of lignin as the glue that holds plants’ fibers together) to create three types of unprecedented wood materials: “One that’s super strong, one that’s super insulative, and one that’s super transparent,” says CEO Josh Cable.

One of InventWood’s materials, MettleWood, is 20 times stronger than regular wood and can be made even stronger than steel. InventWood aims to create a MettleWood I-beam to replace steel I-beams, which are heavily used in construction. In addition to being far more sustainable, the MettleWood I-beam is 80 percent lighter and estimated to be about 50 percent cheaper, according to the startup. MettleWood is also less porous and far more durable than regular wood, addressing wood’s typical issues including fire, termites, and fungus.

MettleWood is InventWood’s primary focus currently, and the startup is exploring applications in building cladding, siding, flooring, and decking. Across these applications, MettleWood could replace significant portions of the steel, concrete, and hard plastics used in buildings today, leading to meaningful decarbonization.

InventWood’s second advanced wood material is highly insulative and can be used in new or retrofitted buildings. The ability to retrofit buildings is crucial, as about two-thirds of buildings today will still exist in 2040. This even opens up a path for renters to insulate their own residences by affixing the insulating wood on top of walls, similar to any other wall decoration. Another possible application of this insulative technology is to replace polystyrene packaging, Cable says.

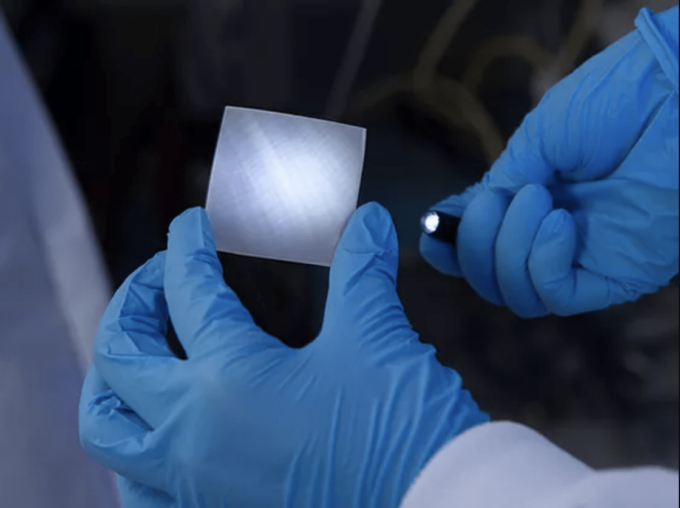

The third wood material is transparent, and three times more insulating than glass. For buildings, the primary application is windows. The climate impact here is clear: in residential buildings, for instance, energy transfer through windows is responsible for 25 to 30 percent of heating and cooling use. This wood technology also has the wide-ranging potential to replace various plastics, including in electronics and packaging.

InventWood is clearly creating sustainable alternatives to steel, concrete, and plastic, but just how sustainable are its materials? Cable says that with climate-conscious deployment, the MettleWood material can be net-negative in terms of emissions due to its highly sequestrated carbon content and outstanding stability. In other words, atmospheric carbon that was captured by trees can be stored long-term in buildings in the form of wood.

“What we’re doing, essentially, is taking carbon out of the atmosphere and storing it in buildings—and bringing value through that storage,” Cable says.

InventWood has spent recent months participating in the Healthy Buildings Challenge, a Greentown Launch program with Saint-Gobain and supported by the Massachusetts Clean Energy Center. The program is advancing building tech solutions for the health of both people and the climate.

For InventWood, the Healthy Buildings Challenge has been an opportunity to understand Saint-Gobain’s needs and explore bringing a product to market together. The program has also helped InventWood zero in on its key applications, according to Cable.

“It’s been a phenomenal opportunity and one of the best things that’s happened to InventWood,” he says. “It’s an incredibly valuable program, and the mentorship has been phenomenal.”

The startup plans to double its team over the next year, in addition to bringing a MettleWood product to market and building out the company’s infrastructure.

InventWood was founded in 2016 as a faculty-led spin-off company of the University of Maryland. Cable joined a year later; after spending a decade in financial services, he wanted to help the planet and made the leap to climatetech.

“A key driver for me was that this material has the potential to be a gamechanger to decarbonize buildings and reduce plastic waste,” he says.