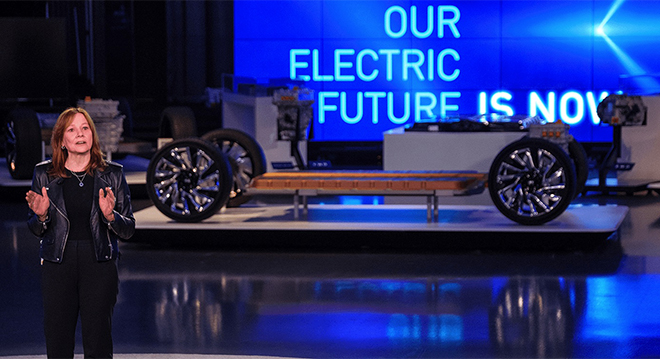

If GM is going to electrify most of its lineup by 2035, it’s going to need a lot more batteries. Sending out press releases is fast and free, but building supply chains takes years and billions, so one indication of whether the automaker’s announced deadline is a serious objective or a mere aspiration will be the steps it takes in the here and now to start building battery capacity.

That’s why we’re pleased to hear GM’s announcement that it’s evaluating a site in Spring Hill, Tennessee, to build a new multibillion-dollar battery factory with partner LG Energy Solutions. The new plant is expected to be similar in size and capacity to the battery factory that GM and LG are currently building in Ohio’s Voltage Valley.

“General Motors and LG Energy Solutions via the Ultium Cells LLC joint venture are exploring the feasibility of constructing a second state-of-the-art battery cell manufacturing plant in the United States,” said GM spokesman Dan Flores. “We hope to have a decision on the potential project in the first half of 2021.”

“We can’t comment on the specifics…but we’re under discussion to make further investments with GM,” said LG Senior VP Seungse Chang. “LG Energy Solutions is also planning additional capacity expansion for other global manufacturers located in the US.”

A source “familiar with the project” told the Detroit Free Press that GM and LG plan to invest about $2.2 billion in the new battery factory, and will conduct “a study to secure local and state tax incentives to build there.”

The new Cadillac Lyriq electric SUV will be the first EV produced at GM’s Spring Hill Assembly plant. It’s expected to go on sale in the first quarter of 2022.

“GM has said they will build EVs at Spring Hill so it makes sense to build a battery factory there,” said Sam Abuelsamid, Principal Analyst at Guidehouse Insights. “Batteries are heavy and bulky and there is risk in transporting them, so what we’ll see going forward is that battery assembly will be done near where the EVs are being built, within a few hours’ drive to the assembly plants.”

By this logic, Michigan could also be a site for a future battery factory, Abuelsamid added. “LG Chem already has a plant of its own in Holland, Michigan, so that’s one source that could expand to supply Ultium batteries. When they originally set up that plant, they had enough land there for three factories.”

If GM expects “to get to 100% EV sales by 2035 or even a million a year in 2025, which is what they talked about recently, they will absolutely need more battery capacity,” says Abuelsamid.

GM CEO Mary Barra acknowledged the critical need for a reliable supply of batteries during last month’s earnings call. “It’s one of the reasons why we’re investing in our own cell manufacturer. There’s more coming than what we’ve announced already. We want to be in control of our own destiny, not only from making sure we have the ability to have the cells that we need but also to work on cost improvements and technology improvements.”

Source: Detroit Free Press